Big Bags and Sacks Unloader

At Equipos y Procesos Levante we design and manufacture complete and customised installations for the handling and emptying of both Big Bags and sacks. We offer everything from individual equipment to complete turnkey installations (EPC).

All our Big Bag unloading stations are modular, which allows them to be easily configured with various components, ensuring proper operation at each unload.

Our BBV series Big Bag emptying stations can be configured according to the following components:

Components

- Placing of the sack with a hoist or trolley.

- Massagers

- Airtight unloading systems

- Lateral anti-bridging systems.

- Vibrating plates.

- Static or dynamic weighing systems.

- Dosing equipment.

- Pneumatic conveying equipment.

- Self-tightening bagging systems.

- Flow switches, automatic or manual.

- Sifting systems.

Our SCV series bag unloading stations can be configured according to the following components:

Components

- Suction and filtering systems.

- Static or dynamic safety sieves.

- Bag breaker.

- Empty bag extractor and collector.

- Up-and-over doors with support tray.

- Unloading assistance systems.

- Mixed configuration (Unloading of sacks and Big Bags).

- Weighing systems.

- Connection with transfer equipment (auger, rotary, etc).

Big Bags and Sacks Unloader

At Equipos y Procesos Levante we design and manufacture complete and customised installations for the handling and emptying of both Big Bags and sacks. We offer everything from individual equipment to complete turnkey installations (EPC).

All our Big Bag unloading stations are modular, which allows them to be easily configured with various components, ensuring proper operation at each unload.

Our BBV series Big Bag emptying stations can be configured according to the following components:

Componentes

- Placing of the sack with a hoist or trolley.

- Massagers

- Airtight unloading systems

- Lateral anti-bridging systems.

- Vibrating plates.

- Static or dynamic weighing systems.

- Dosing equipment.

- Pneumatic conveying equipment.

- Self-tightening bagging systems.

- Flow switches, automatic or manual.

- Sifting systems.

Our SCV series bag unloading stations can be configured according to the following components:

Componentes

- Suction and filtering systems.

- Static or dynamic safety sieves.

- Bag breaker.

- Empty bag extractor and collector.

- Up-and-over doors with support tray.

- Unloading assistance systems.

- Mixed configuration (Unloading of sacks and Big Bags).

- Weighing systems.

- Connection with transfer equipment (auger, rotary, etc).

Big Bags and Sacks Unloader

At Equipos y Procesos Levante we design and manufacture complete and customised installations for the handling and emptying of both Big Bags and sacks. We offer everything from individual equipment to complete turnkey installations (EPC).

All our Big Bag unloading stations are modular, which allows them to be easily configured with various components, ensuring proper operation at each unload.

Our BBV series Big Bag emptying stations can be configured according to the following components:

Componentes

- Placing of the sack with a hoist or trolley.

- Massagers

- Airtight unloading systems

- Lateral anti-bridging systems.

- Vibrating plates.

- Static or dynamic weighing systems.

- Dosing equipment.

- Pneumatic conveying equipment.

- Self-tightening bagging systems.

- Flow switches, automatic or manual.

- Sifting systems.

Our SCV series bag unloading stations can be configured according to the following components:

Componentes

- Suction and filtering systems.

- Static or dynamic safety sieves.

- Bag breaker.

- Empty bag extractor and collector.

- Up-and-over doors with support tray.

- Unloading assistance systems.

- Mixed configuration (Unloading of sacks and Big Bags).

- Weighing systems.

- Connection with transfer equipment (auger, rotary, etc).

Dosing and weighing for solid and liquid bulk materials

In Equipment and Processes we design and manufacture complete custom installations for the dosing and weighing of solid and liquid bulk materials. We offer from individual systems to complete “turnkey” installations.

A weighing system for your tank or hopper allows you to visualize the weight of your content and a wide variety of functions that will enhance your production processes.

Dosing and weighing for solid and liquid bulk materials

In Equipment and Processes we design and manufacture complete custom installations for the dosing and weighing of solid and liquid bulk materials. We offer from individual systems to complete “turnkey” installations.

A weighing system for your tank or hopper allows you to visualize the weight of your content and a wide variety of functions that will enhance your production processes.

Dosing and weighing for solid and liquid bulk materials

In Equipment and Processes we design and manufacture complete custom installations for the dosing and weighing of solid and liquid bulk materials. We offer from individual systems to complete “turnkey” installations.

A weighing system for your tank or hopper allows you to visualize the weight of your content and a wide variety of functions that will enhance your production processes.

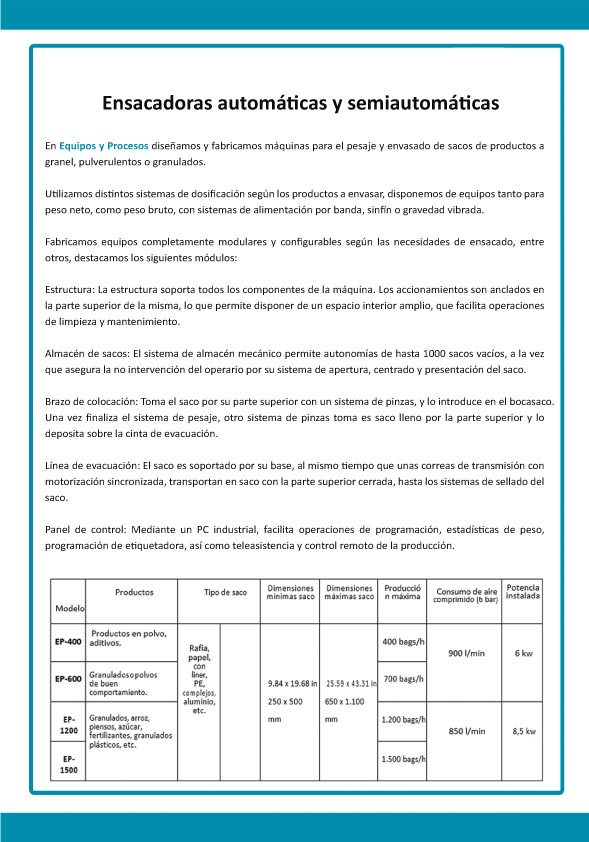

Bagging machines

At Equipos y Procesos Levante we design and manufacture machines for weighing and packing bags of solid bulk materials, both for powder and granular products.

We use different dosing systems depending on the products to be packed, we have equipment for both net and gross weight, with belt, auger or vibratory gravity feeding systems. We manufacture according to your bagging needs.

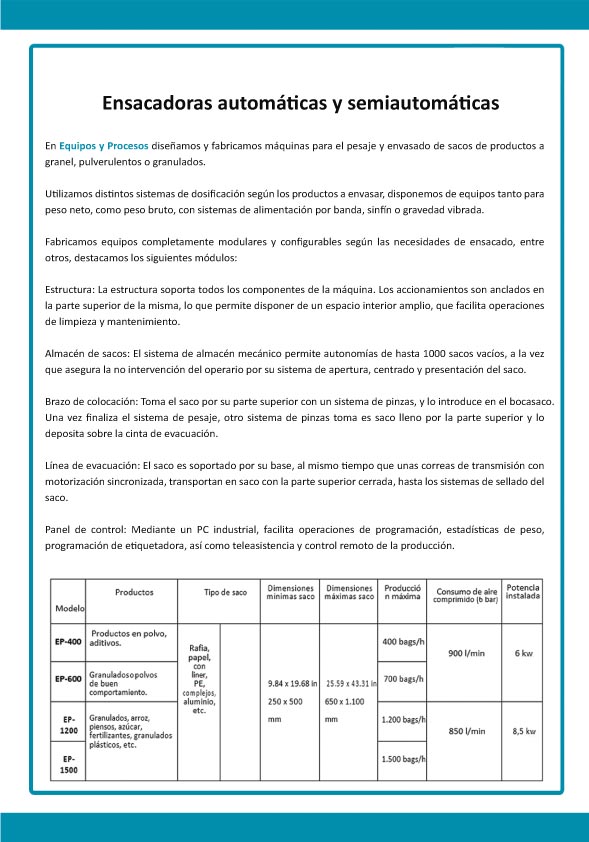

Bagging machines

At Equipos y Procesos Levante we design and manufacture machines for weighing and packing bags of solid bulk materials, both for powder and granular products.

We use different dosing systems depending on the products to be packed, we have equipment for both net and gross weight, with belt, auger or vibratory gravity feeding systems. We manufacture according to your bagging needs.

Bagging

machines

At Equipos y Procesos Levante we design and manufacture machines for weighing and packing bags of solid bulk materials, both for powder and granular products.

We use different dosing systems depending on the products to be packed, we have equipment for both net and gross weight, with belt, auger or vibratory gravity feeding systems. We manufacture according to your bagging needs.

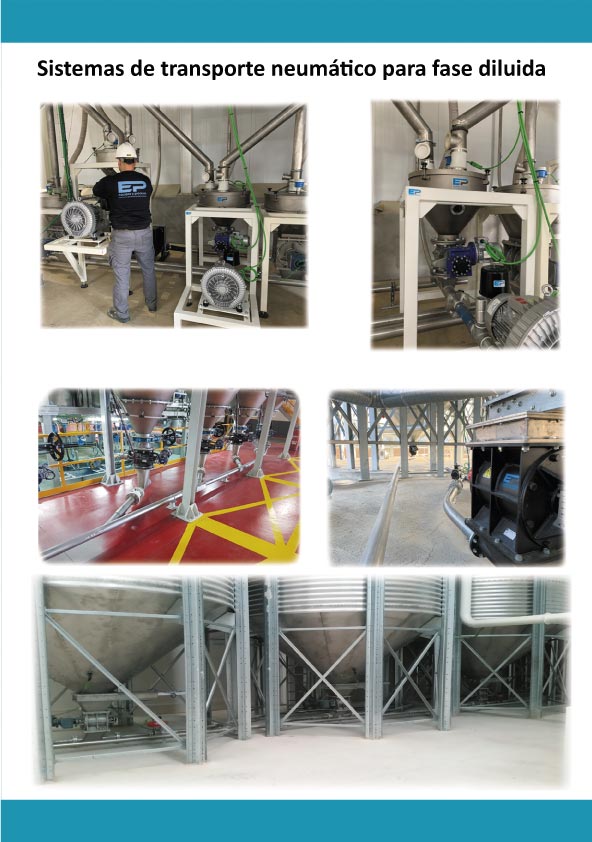

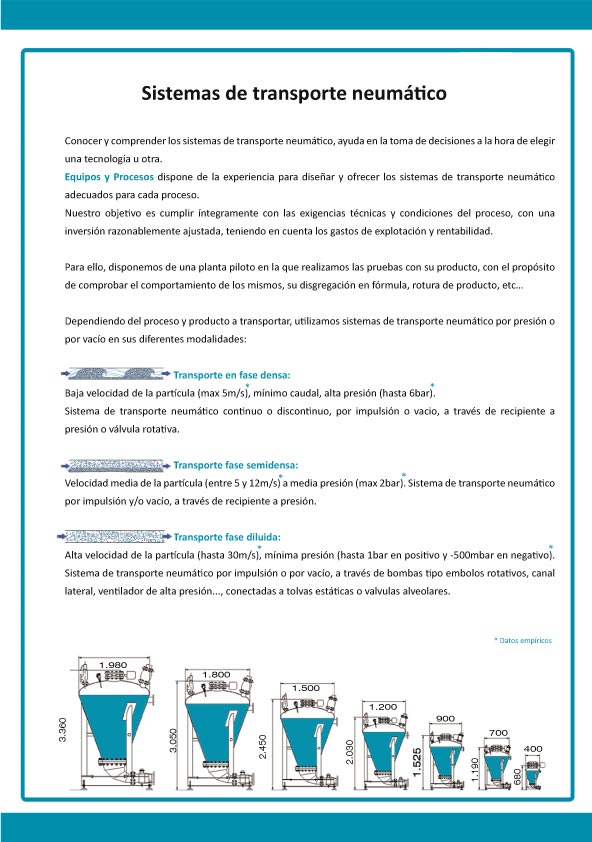

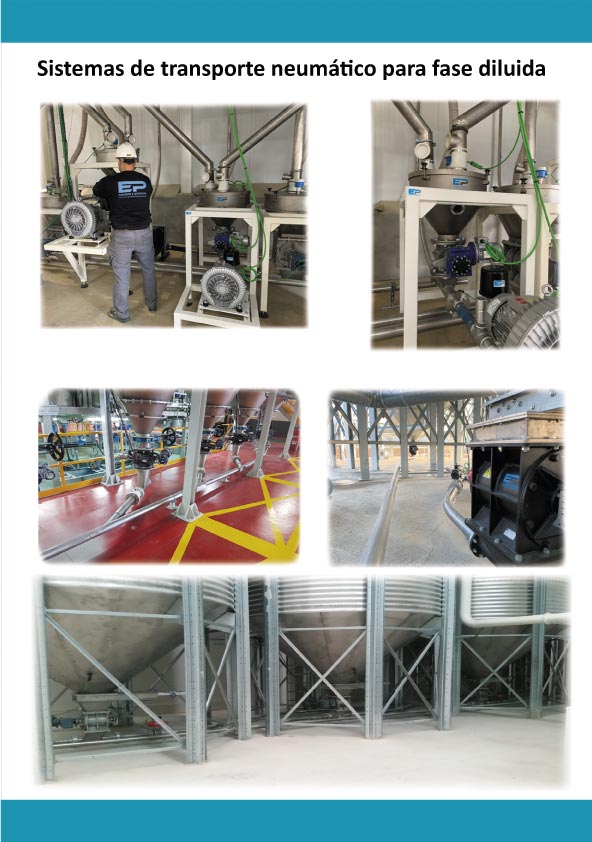

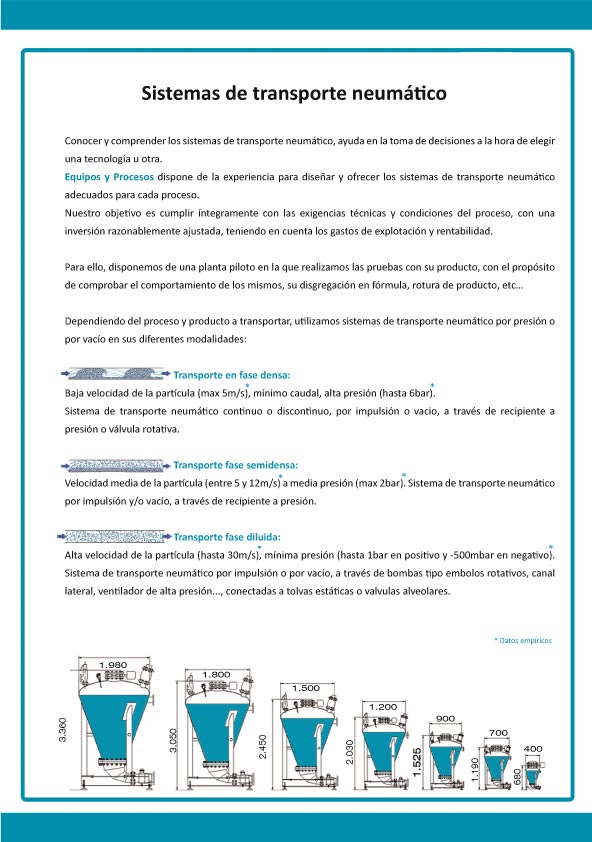

Pneumatic conveying

systems

Knowing and understanding pneumatic conveying systems helps in making decisions when choosing one technology or another. Equipos y Procesos Levante has the experience to design and offer the ideal pneumatic conveying systems for each process.

Our objective is to fully comply with the technical requirements and conditions of each process, with a reasonable and controlled investment taking into account the operating costs and profitability. For this purpose, we have a pilot plant to carry out industrial level tests with your product, checking its behaviour, breakage and disintegration, in order to offer you, with total security, the equipment that best suits your needs.

Depending on the process and product to be conveyed, we use pressure or vacuum pneumatic conveying systems in their different modalities.

Pneumatic conveying systems

Knowing and understanding pneumatic conveying systems helps in making decisions when choosing one technology or another. Equipos y Procesos Levante has the experience to design and offer the ideal pneumatic conveying systems for each process.

Our objective is to fully comply with the technical requirements and conditions of each process, with a reasonable and controlled investment taking into account the operating costs and profitability. For this purpose, we have a pilot plant to carry out industrial level tests with your product, checking its behaviour, breakage and disintegration, in order to offer you, with total security, the equipment that best suits your needs.

Depending on the process and product to be conveyed, we use pressure or vacuum pneumatic conveying systems in their different modalities.

Pneumatic conveying

systems

Knowing and understanding pneumatic conveying systems helps in making decisions when choosing one technology or another. Equipos y Procesos Levante has the experience to design and offer the ideal pneumatic conveying systems for each process.

Our objective is to fully comply with the technical requirements and conditions of each process, with a reasonable and controlled investment taking into account the operating costs and profitability. For this purpose, we have a pilot plant to carry out industrial level tests with your product, checking its behaviour, breakage and disintegration, in order to offer you, with total security, the equipment that best suits your needs.

Depending on the process and product to be conveyed, we use pressure or vacuum pneumatic conveying systems in their different modalities.

New Series

Evo-pneumatic

The constant evolution of the industry towards intelligent processes, such as the new manufacturing 4.0 concepts, means that our R&D&i team is constantly evolving, allowing the use of the best available techniques (BAT). As a result, this equipment is unique in the market.

The latest generation evo model Dense Phase Pneumatic Conveying equipment from Equipos y Procesos Levante, mixes optimum design with the latest technology in process control in order to optimise energy consumption, since it automatically adjusts the regulation in both flow and pressure, thus adapting itself to the properties of each raw material.

After years of experience, development and manufacture of pneumatic conveying equipment and installations, one of the learning qualities offered by part of the experience is to define the real needs in each process and its limitations.

These limitations and needs have led to the creation of EVO-PNEUMATIC. Compact, simple and intelligent equipment, which adapts and learns about any raw material to be transferred.

New Series

Evo-pneumatic

The constant evolution of the industry towards intelligent processes, such as the new manufacturing 4.0 concepts, means that our R&D&i team is constantly evolving, allowing the use of the best available techniques (BAT). As a result, this equipment is unique in the market.

The latest generation evo model Dense Phase Pneumatic Conveying equipment from Equipos y Procesos Levante, mixes optimum design with the latest technology in process control in order to optimise energy consumption, since it automatically adjusts the regulation in both flow and pressure, thus adapting itself to the properties of each raw material.

After years of experience, development and manufacture of pneumatic conveying equipment and installations, one of the learning qualities offered by part of the experience is to define the real needs in each process and its limitations.

These limitations and needs have led to the creation of EVO-PNEUMATIC. Compact, simple and intelligent equipment, which adapts and learns about any raw material to be transferred.

New Series

Evo-pneumatic

The constant evolution of the industry towards intelligent processes, such as the new manufacturing 4.0 concepts, means that our R&D&i team is constantly evolving, allowing the use of the best available techniques (BAT). As a result, this equipment is unique in the market.

The latest generation evo model Dense Phase Pneumatic Conveying equipment from Equipos y Procesos Levante, mixes optimum design with the latest technology in process control in order to optimise energy consumption, since it automatically adjusts the regulation in both flow and pressure, thus adapting itself to the properties of each raw material.

After years of experience, development and manufacture of pneumatic conveying equipment and installations, one of the learning qualities offered by part of the experience is to define the real needs in each process and its limitations.

These limitations and needs have led to the creation of EVO-PNEUMATIC. Compact, simple and intelligent equipment, which adapts and learns about any raw material to be transferred.

EPC Projects

EPC (Engineering, Procurement and Construction) refers to everything included in the contract: the design, the necessary supplies and the construction. Also included are a number of additional services that are necessary to meet these three main objectives of design, supply and construction.

Equipos y Procesos Levante offers a full guarantee of efficiency in the implementation of the project. The responsibility lies in our hands, relieving investors of the risk inherent in contracts with suppliers.

The contractual EPC or “turnkey” solution guarantees compensation for delays in project completion and also assumes full responsibility for the total project cost and performance as defined in the contract.

We design the project you need to maximise production, we procure the equipment and materials and we handle the execution of the entire installation.

The customer receives the installation or the work needed, at the price agreed at the beginning of the contract, leaving us with the task of coordinating all the work until its completion.

The single point of control over the design of the entire plant and the management of the project under the EPC contract favours the homogeneity of the plant, as well as that of equipment and materials in general.

EPC Projects

EPC (Engineering, Procurement and Construction) refers to everything included in the contract: the design, the necessary supplies and the construction. Also included are a number of additional services that are necessary to meet these three main objectives of design, supply and construction.

Equipos y Procesos Levante offers a full guarantee of efficiency in the implementation of the project. The responsibility lies in our hands, relieving investors of the risk inherent in contracts with suppliers.

The contractual EPC or “turnkey” solution guarantees compensation for delays in project completion and also assumes full responsibility for the total project cost and performance as defined in the contract.

We design the project you need to maximise production, we procure the equipment and materials and we handle the execution of the entire installation.

The customer receives the installation or the work needed, at the price agreed at the beginning of the contract, leaving us with the task of coordinating all the work until its completion.

The single point of control over the design of the entire plant and the management of the project under the EPC contract favours the homogeneity of the plant, as well as that of equipment and materials in general.

EPC Projects

EPC (Engineering, Procurement and Construction) refers to everything included in the contract: the design, the necessary supplies and the construction. Also included are a number of additional services that are necessary to meet these three main objectives of design, supply and construction.

Equipos y Procesos Levante offers a full guarantee of efficiency in the implementation of the project. The responsibility lies in our hands, relieving investors of the risk inherent in contracts with suppliers.

The contractual EPC or “turnkey” solution guarantees compensation for delays in project completion and also assumes full responsibility for the total project cost and performance as defined in the contract.

We design the project you need to maximise production, we procure the equipment and materials and we handle the execution of the entire installation.

The customer receives the installation or the work needed, at the price agreed at the beginning of the contract, leaving us with the task of coordinating all the work until its completion.

The single point of control over the design of the entire plant and the management of the project under the EPC contract favours the homogeneity of the plant, as well as that of equipment and materials in general.

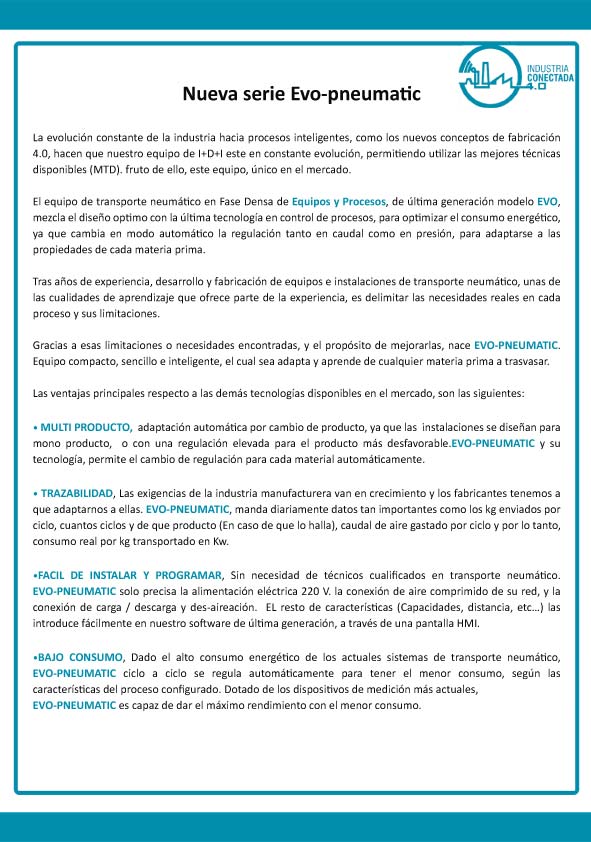

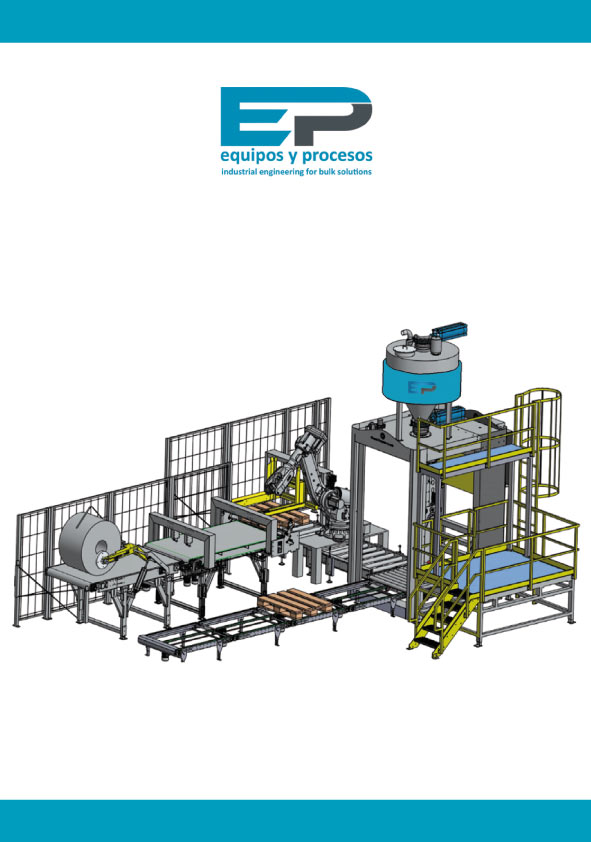

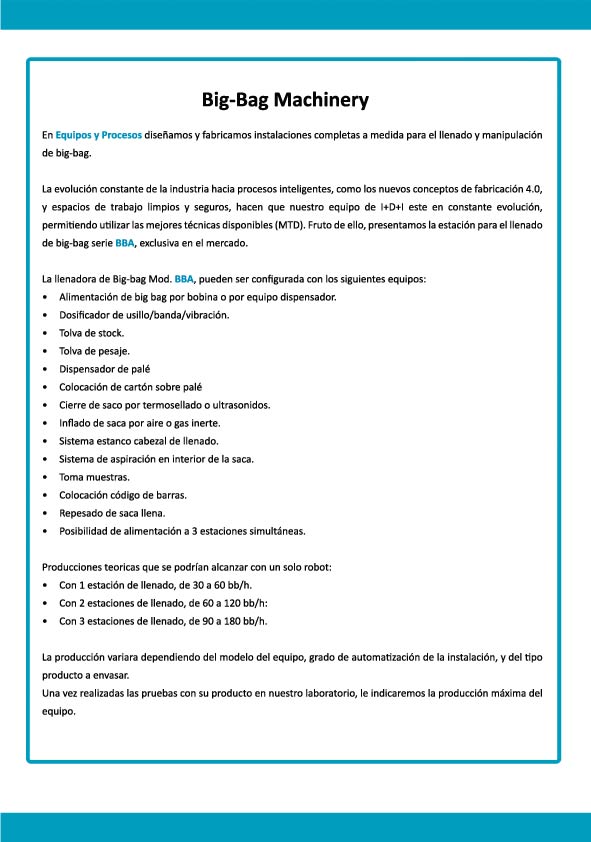

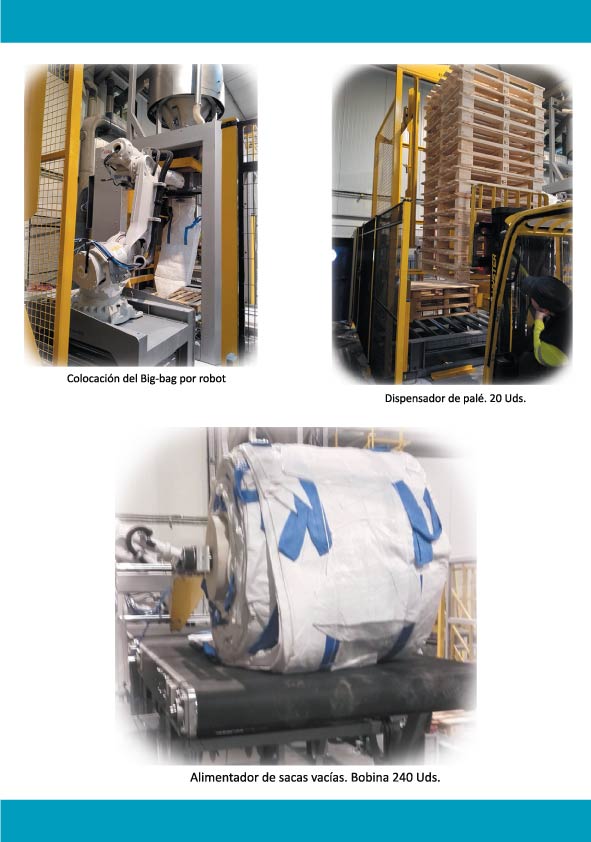

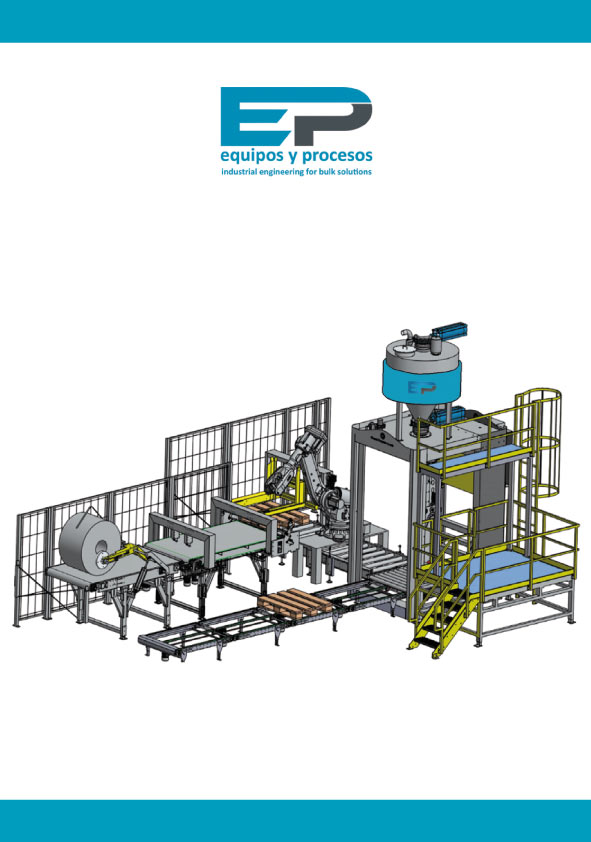

Automatic filling machines

At Equipos y Procesos we design and manufacture complete customised installations for the filling and handling of Big Bags.

The constant evolution of the industry towards intelligent processes, such as the new manufacturing 4.0 concepts, means that our R&D&i team is constantly evolving, allowing the use of the best available techniques (BAT). As a result, this equipment is unique in the market.

Producciones teóricas que se podrían alcanzar con un sólo robot:

- with 1 filling station, semi-automatic: 30 – 60 bb/h

- with 2 filling station, semi-automatic: 60 – 120 bb/h

- with 3 filling station, semi-automatic: 90 – 180 bb/h

The throughput will vary depending on the model of the equipment, the degree of automation of the installation and the type of product to be packed. Once the tests with your product have been carried out in our laboratory, we will indicate the maximum throughput from the equipment.

The basic functions of the Big Bag filling station, automatic BBA series are as follows:

Basic functions

- Weighing hopper.

- Weighing on roller conveyors

- Belt, chain or roller conveyors

- Pallet dispenser

- Placing of cardboard on pallets

- Placing of film on pallets

- Airtight system in filling head

- Suction system inside the bag

- Bag inflation with air or nitrogen

- Sample collection

- Product compacting on roller conveyor

- Heat sealing or ultrasonic bag closing

- Barcode attachment

- Reweighing and checking of full Big Bags

Automatic filling machines

At Equipos y Procesos we design and manufacture complete customised installations for the filling and handling of Big Bags.

The constant evolution of the industry towards intelligent processes, such as the new manufacturing 4.0 concepts, means that our R&D&i team is constantly evolving, allowing the use of the best available techniques (BAT). As a result, this equipment is unique in the market.

Producciones teóricas que se podrían alcanzar con un sólo robot:

with 1 filling station, semi-automatic: 30 – 60 bb/h

with 2 filling station, semi-automatic: 60 – 120 bb/h

with 3 filling station, semi-automatic: 90 – 180 bb/h

The throughput will vary depending on the model of the equipment, the degree of automation of the installation and the type of product to be packed. Once the tests with your product have been carried out in our laboratory, we will indicate the maximum throughput from the equipment.

The basic functions of the Big Bag filling station, automatic BBA series are as follows:

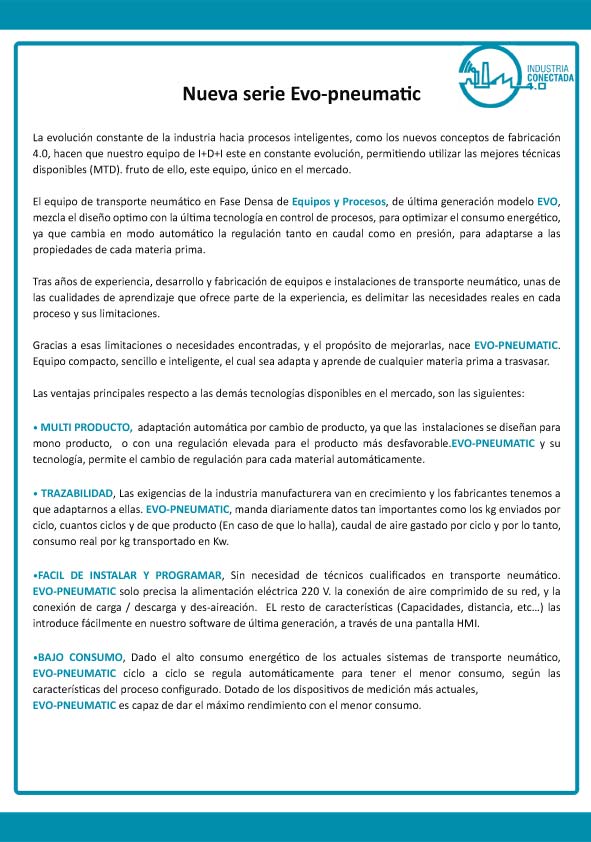

Basic functions

- Weighing hopper.

- Weighing on roller conveyors

- Belt, chain or roller conveyors

- Pallet dispenser

- Placing of cardboard on pallets

- Placing of film on pallets

- Airtight system in filling head

- Suction system inside the bag

- Bag inflation with air or nitrogen

- Sample collection

- Product compacting on roller conveyor

- Heat sealing or ultrasonic bag closing

- Barcode attachment

- Reweighing and checking of full Big Bags

Automatic filling machines

At Equipos y Procesos we design and manufacture complete customised installations for the filling and handling of Big Bags.

The constant evolution of the industry towards intelligent processes, such as the new manufacturing 4.0 concepts, means that our R&D&i team is constantly evolving, allowing the use of the best available techniques (BAT). As a result, this equipment is unique in the market.

Producciones teóricas que se podrían alcanzar con un sólo robot:

- with 1 filling station, semi-automatic: 30 – 60 bb/h

- with 2 filling station, semi-automatic: 60 – 120 bb/h

- with 3 filling station, semi-automatic: 90 – 180 bb/h

The throughput will vary depending on the model of the equipment, the degree of automation of the installation and the type of product to be packed. Once the tests with your product have been carried out in our laboratory, we will indicate the maximum throughput from the equipment.

The basic functions of the Big Bag filling station, automatic BBA series are as follows:

Basic functions

- Weighing hopper.

- Weighing on roller conveyors

- Belt, chain or roller conveyors

- Pallet dispenser

- Placing of cardboard on pallets

- Placing of film on pallets

- Airtight system in filling head

- Suction system inside the bag

- Bag inflation with air or nitrogen

- Sample collection

- Product compacting on roller conveyor

- Heat sealing or ultrasonic bag closing

- Barcode attachment

- Reweighing and checking of full Big Bags

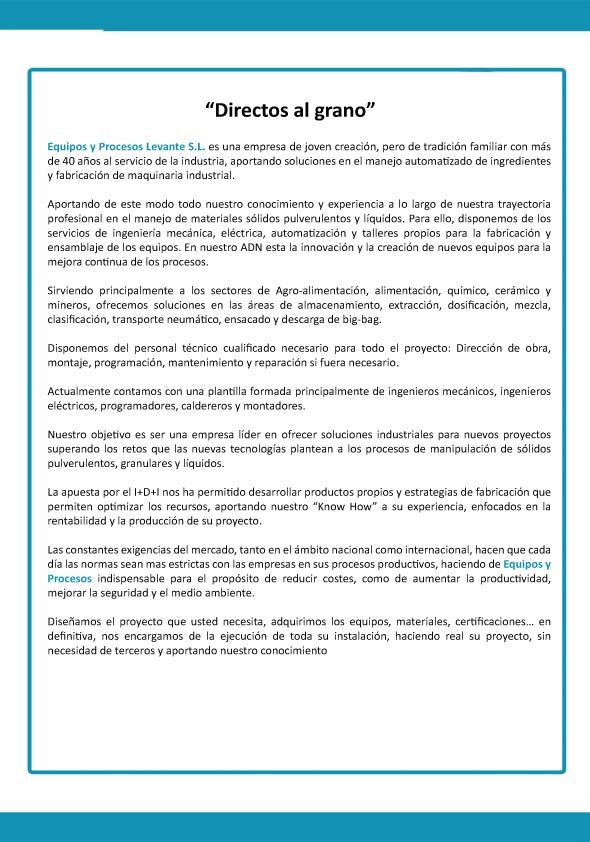

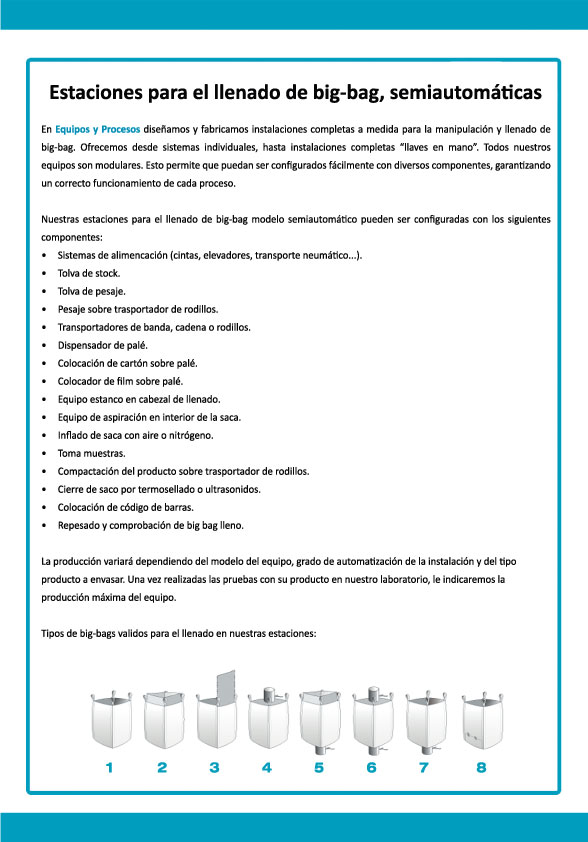

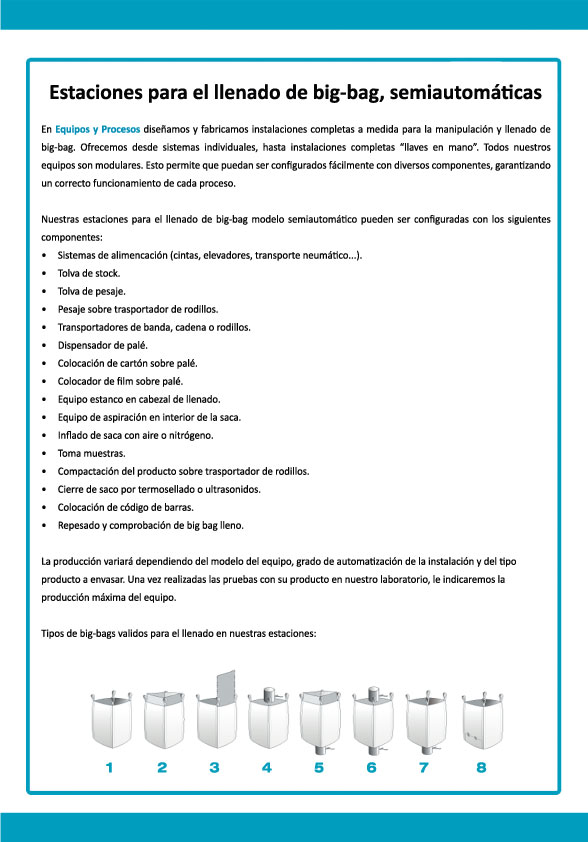

Semi-automatic filling machines

At Equipos y Procesos we design and manufacture complete customised installations for the filling and handling of Big Bags. We have standard equipment to provide a quick and economical response, but we also adapt to the needs of each process, designing and adapting our equipment for its optimal application.

The throughput of our equipment varies mainly depending on the product to be packaged, the type of filling station chosen and its degree of automation. Once the tests with your product have been carried out in our laboratory, we will indicate the maximum throughput of the equipment.

All our equipment is modular, this allows it to be configured with different accessories:

Components

- Weighing hopper.

- Weighing on roller conveyors

- Belt, chain or roller conveyors

- Pallet dispenser

- Placing of cardboard on pallets

- Placing of film on pallets

- Airtight system in filling head

- Suction system inside the bag

- Bag inflation with air or nitrogen

- Sample collection

- Product compacting on roller conveyor

- Heat sealing or ultrasonic bag closing

- Barcode attachment

- Reweighing and checking of full Big Bags

Semi-automatic filling machines

At Equipos y Procesos we design and manufacture complete customised installations for the filling and handling of Big Bags. We have standard equipment to provide a quick and economical response, but we also adapt to the needs of each process, designing and adapting our equipment for its optimal application.

The throughput of our equipment varies mainly depending on the product to be packaged, the type of filling station chosen and its degree of automation. Once the tests with your product have been carried out in our laboratory, we will indicate the maximum throughput of the equipment.

All our equipment is modular, this allows it to be configured with different accessories:

Componentes

- Weighing hopper.

- Weighing on roller conveyors

- Belt, chain or roller conveyors

- Pallet dispenser

- Placing of cardboard on pallets

- Placing of film on pallets

- Airtight system in filling head

- Suction system inside the bag

- Bag inflation with air or nitrogen

- Sample collection

- Product compacting on roller conveyor

- Heat sealing or ultrasonic bag closing

- Barcode attachment

- Reweighing and checking of full Big Bags

Semi-automatic filling machines

At Equipos y Procesos we design and manufacture complete customised installations for the filling and handling of Big Bags. We have standard equipment to provide a quick and economical response, but we also adapt to the needs of each process, designing and adapting our equipment for its optimal application.

The throughput of our equipment varies mainly depending on the product to be packaged, the type of filling station chosen and its degree of automation. Once the tests with your product have been carried out in our laboratory, we will indicate the maximum throughput of the equipment.

All our equipment is modular, this allows it to be configured with different accessories:

Componentes

- Weighing hopper.

- Weighing on roller conveyors

- Belt, chain or roller conveyors

- Pallet dispenser

- Placing of cardboard on pallets

- Placing of film on pallets

- Airtight system in filling head

- Suction system inside the bag

- Bag inflation with air or nitrogen

- Sample collection

- Product compacting on roller conveyor

- Heat sealing or ultrasonic bag closing

- Barcode attachment

- Reweighing and checking of full Big Bags

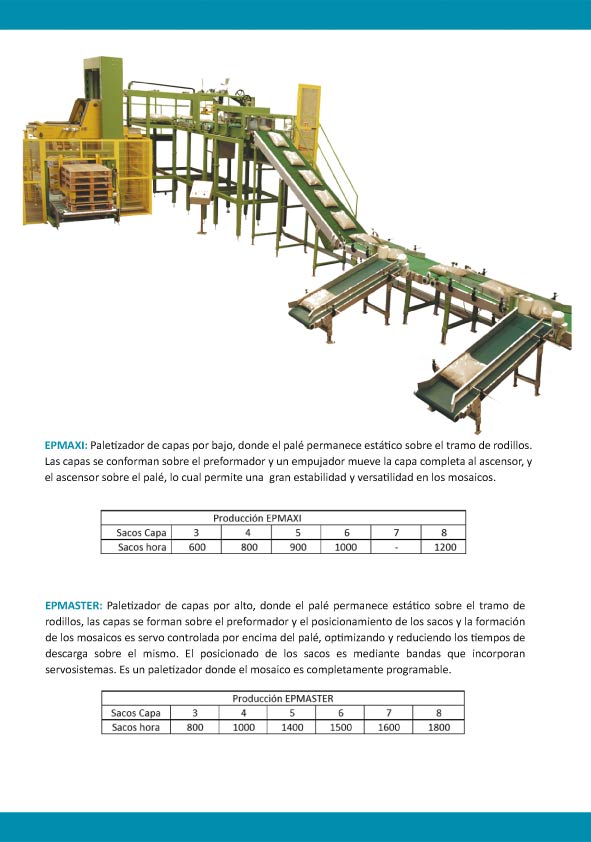

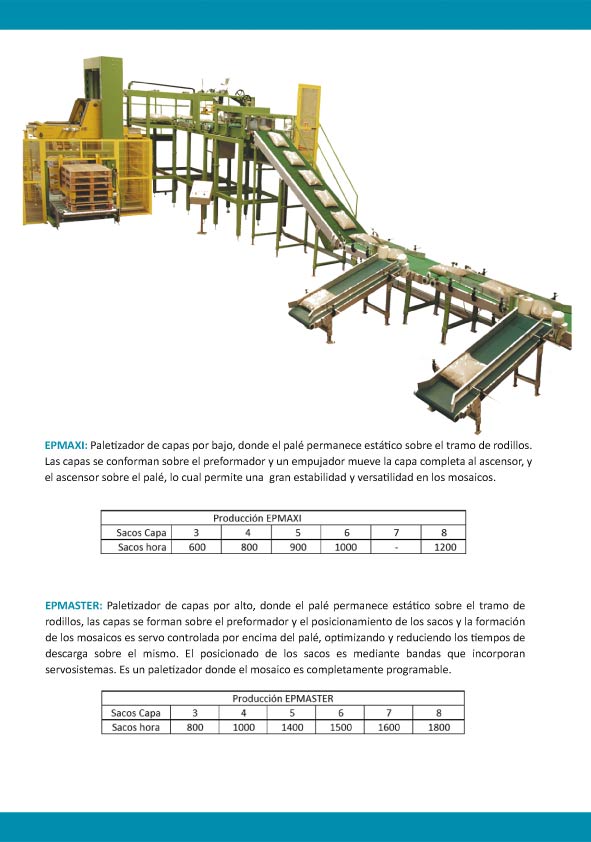

Palletisers

La producción variará dependiendo del modelo del equipo, grado de automatización de la instalación y del tipo del producto a envasar. Una vez realizadas las pruebas con su producto en nuestro laboratorio, le indicaremos la producción máxima del equipo.

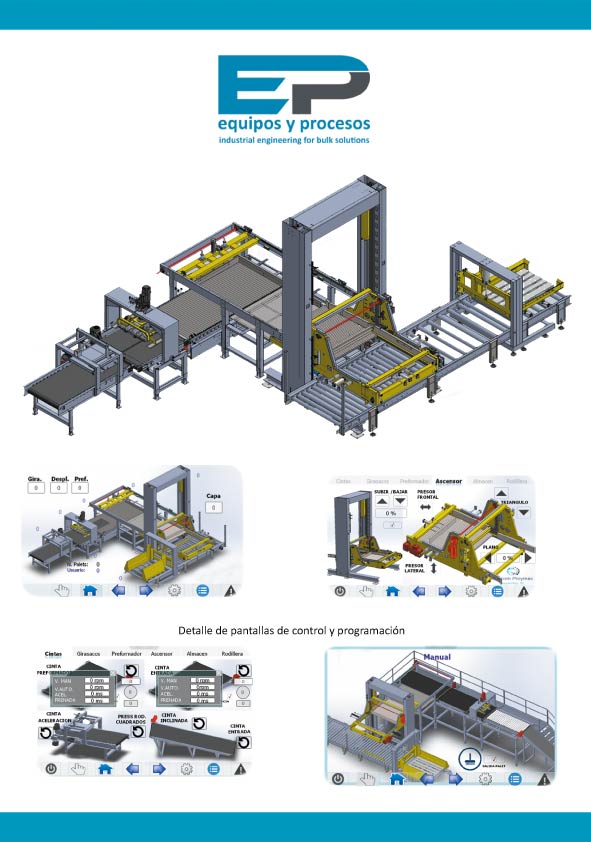

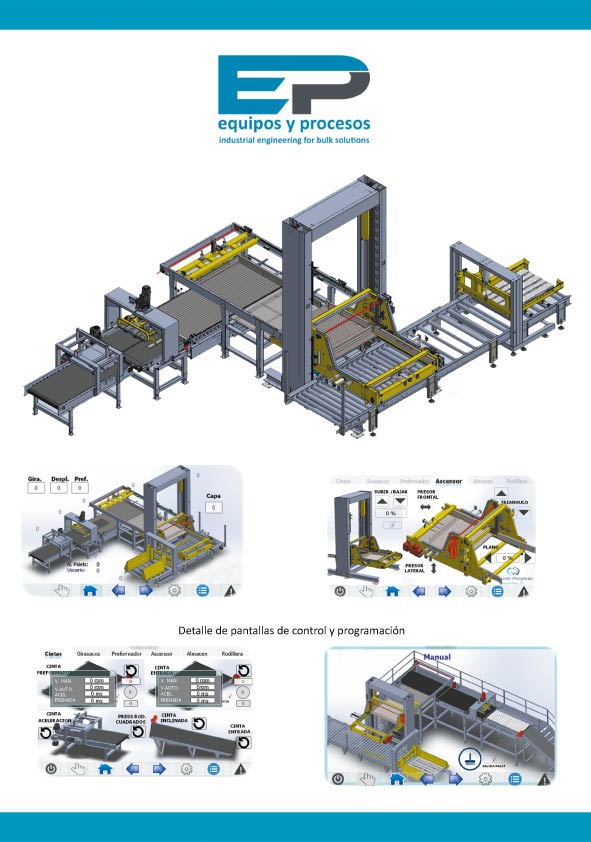

En Equipos y procesos, ofrecemos soluciones automáticas para la paletización, diseñamos y fabricamos equipos que se ajustan a las necesidades de nuestros clientes. Nuestros equipos son válidos para paletizar todo tipo de sacos, cajas y envases en general.

Los paletizadores por capas tienen la gran ventaja, conformar las capas lateralmente antes de depositarlas sobre el palé, trasladado la capa completa de sacos al mismo tiempo, de este modo, aumentan la calidad de paletizado y la velocidad.

Fabricamos equipos completamente modulares y configurables según las necesidades de paletizado, entre otros, destacamos los siguientes módulos

Todos nuestros equipos van dotados de un sistema de control muy visual e intuitivo, fácil de manejar y configurar, aumentado flexibilidad y rapidez en cambios de formato. Ofrecemos servicios de tele asistencia para dar soporte técnico y minimizar tiempos de paradas no previstas.

Módulos

-Conformador Pres con rodillos cuadrados: Módulo que nos permite una combinación de compactación del producto mediante el transporte de rodillos cuadrados que distribuyen el producto en el interior del saco, y un posterior prensado. Opción de incluir giro de 180º al saco antes del prensado para evitar roturas por sobrepresión.

-Módulo girasacos: Permite giros de 90º-180º a los sacos para la configuración del mosaico. Está disponible en tres tecnologías según necesidades y complejidad del mismo. Motor asíncrono con frenado por inductivos, motor con encoder y servosistema.

-Módulo desplazador: Es un módulo que aporta variantes en las agrupaciones de sacos y permite empujes de capas completas. Adecuado para mosaicos de sacos entrelazados.

– Módulo ascensor: El módulo ascensor es un sistema rápido y silencioso, que deposita la capa completa sobre el palé, aportando compactación lateral y compactación por prensado.

Palletisers

La producción variará dependiendo del modelo del equipo, grado de automatización de la instalación y del tipo del producto a envasar. Una vez realizadas las pruebas con su producto en nuestro laboratorio, le indicaremos la producción máxima del equipo.

En Equipos y procesos, ofrecemos soluciones automáticas para la paletización, diseñamos y fabricamos equipos que se ajustan a las necesidades de nuestros clientes. Nuestros equipos son válidos para paletizar todo tipo de sacos, cajas y envases en general.

Los paletizadores por capas tienen la gran ventaja, conformar las capas lateralmente antes de depositarlas sobre el palé, trasladado la capa completa de sacos al mismo tiempo, de este modo, aumentan la calidad de paletizado y la velocidad.

Fabricamos equipos completamente modulares y configurables según las necesidades de paletizado, entre otros, destacamos los siguientes módulos

Todos nuestros equipos van dotados de un sistema de control muy visual e intuitivo, fácil de manejar y configurar, aumentado flexibilidad y rapidez en cambios de formato. Ofrecemos servicios de tele asistencia para dar soporte técnico y minimizar tiempos de paradas no previstas.

Módulos

-Conformador Pres con rodillos cuadrados: Módulo que nos permite una combinación de compactación del producto mediante el transporte de rodillos cuadrados que distribuyen el producto en el interior del saco, y un posterior prensado. Opción de incluir giro de 180º al saco antes del prensado para evitar roturas por sobrepresión.

-Módulo girasacos: Permite giros de 90º-180º a los sacos para la configuración del mosaico. Está disponible en tres tecnologías según necesidades y complejidad del mismo. Motor asíncrono con frenado por inductivos, motor con encoder y servosistema.

-Módulo desplazador: Es un módulo que aporta variantes en las agrupaciones de sacos y permite empujes de capas completas. Adecuado para mosaicos de sacos entrelazados.

– Módulo ascensor: El módulo ascensor es un sistema rápido y silencioso, que deposita la capa completa sobre el palé, aportando compactación lateral y compactación por prensado.

Palletisers

La producción variará dependiendo del modelo del equipo, grado de automatización de la instalación y del tipo del producto a envasar. Una vez realizadas las pruebas con su producto en nuestro laboratorio, le indicaremos la producción máxima del equipo.

En Equipos y procesos, ofrecemos soluciones automáticas para la paletización, diseñamos y fabricamos equipos que se ajustan a las necesidades de nuestros clientes. Nuestros equipos son válidos para paletizar todo tipo de sacos, cajas y envases en general.

Los paletizadores por capas tienen la gran ventaja, conformar las capas lateralmente antes de depositarlas sobre el palé, trasladado la capa completa de sacos al mismo tiempo, de este modo, aumentan la calidad de paletizado y la velocidad.

Fabricamos equipos completamente modulares y configurables según las necesidades de paletizado, entre otros, destacamos los siguientes módulos

Todos nuestros equipos van dotados de un sistema de control muy visual e intuitivo, fácil de manejar y configurar, aumentado flexibilidad y rapidez en cambios de formato. Ofrecemos servicios de tele asistencia para dar soporte técnico y minimizar tiempos de paradas no previstas.

Funciones básicas

-Conformador Pres con rodillos cuadrados: Módulo que nos permite una combinación de compactación del producto mediante el transporte de rodillos cuadrados que distribuyen el producto en el interior del saco, y un posterior prensado. Opción de incluir giro de 180º al saco antes del prensado para evitar roturas por sobrepresión.

-Módulo girasacos: Permite giros de 90º-180º a los sacos para la configuración del mosaico. Está disponible en tres tecnologías según necesidades y complejidad del mismo. Motor asíncrono con frenado por inductivos, motor con encoder y servosistema.

-Módulo desplazador: Es un módulo que aporta variantes en las agrupaciones de sacos y permite empujes de capas completas. Adecuado para mosaicos de sacos entrelazados.

– Módulo ascensor: El módulo ascensor es un sistema rápido y silencioso, que deposita la capa completa sobre el palé, aportando compactación lateral y compactación por prensado.

Installations for unloading of toxic products

We have the experience and the equipment to deal with this type of product – our standard model for Big Bag unloading equipped with a completely airtight perimeter enclosure cabin, glassed-in area for visualising the operation, airtight system in the unloading, massagers to guarantee correct unloading.

It also features a bag unloading hopper designed to ensure dust-free unloading of toxic products in complete safety for the operator, equipped with a filter for dust collection and a hinged door with built-in gloves.

Installations for unloading of toxic products

We have the experience and the equipment to deal with this type of product – our standard model for Big Bag unloading equipped with a completely airtight perimeter enclosure cabin, glassed-in area for visualising the operation, airtight system in the unloading, massagers to guarantee correct unloading.

It also features a bag unloading hopper designed to ensure dust-free unloading of toxic products in complete safety for the operator, equipped with a filter for dust collection and a hinged door with built-in gloves.

Installations for unloading of toxic products

We have the experience and the equipment to deal with this type of product – our standard model for Big Bag unloading equipped with a completely airtight perimeter enclosure cabin, glassed-in area for visualising the operation, airtight system in the unloading, massagers to guarantee correct unloading.

It also features a bag unloading hopper designed to ensure dust-free unloading of toxic products in complete safety for the operator, equipped with a filter for dust collection and a hinged door with built-in gloves.