The constant evolution of the industry towards intelligent processes, such as the new manufacturing 4.0 concepts, means that our R&D&i team is constantly evolving, allowing the use of the best available techniques (BAT). As a result, this equipment is unique in the market.

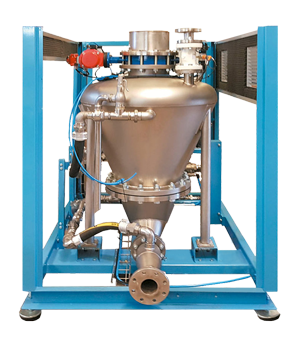

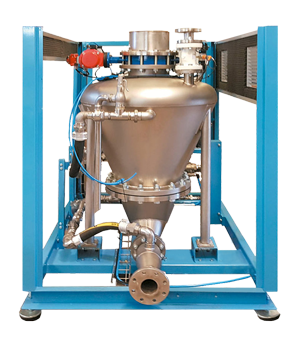

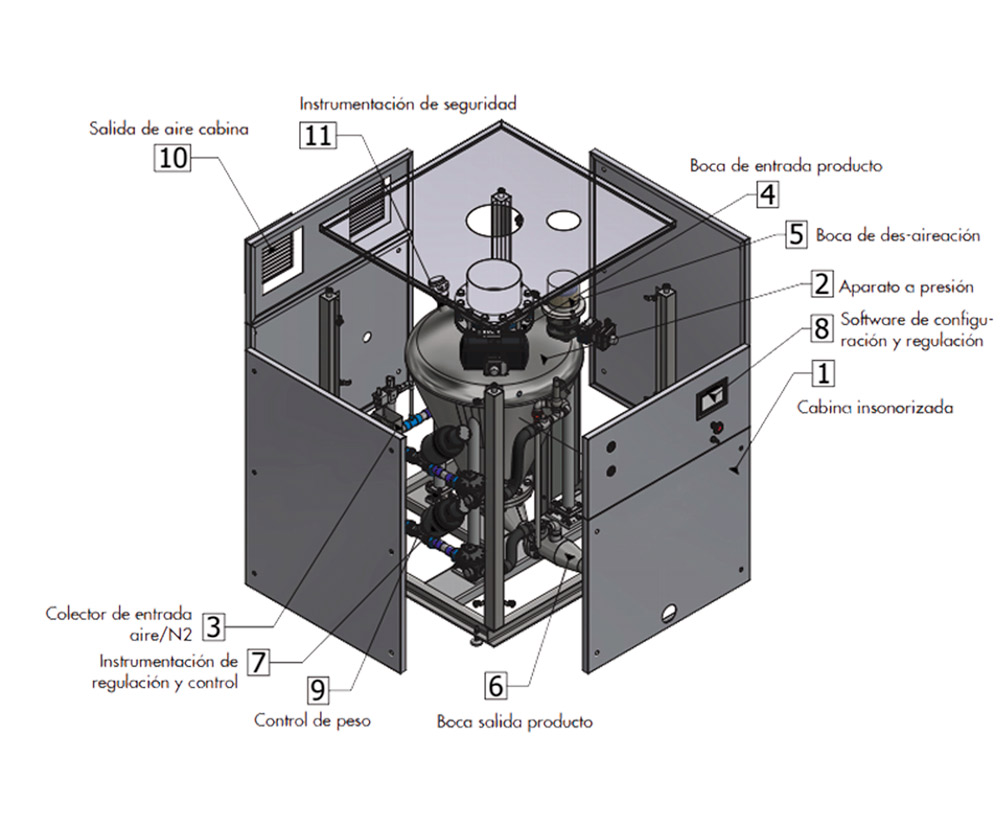

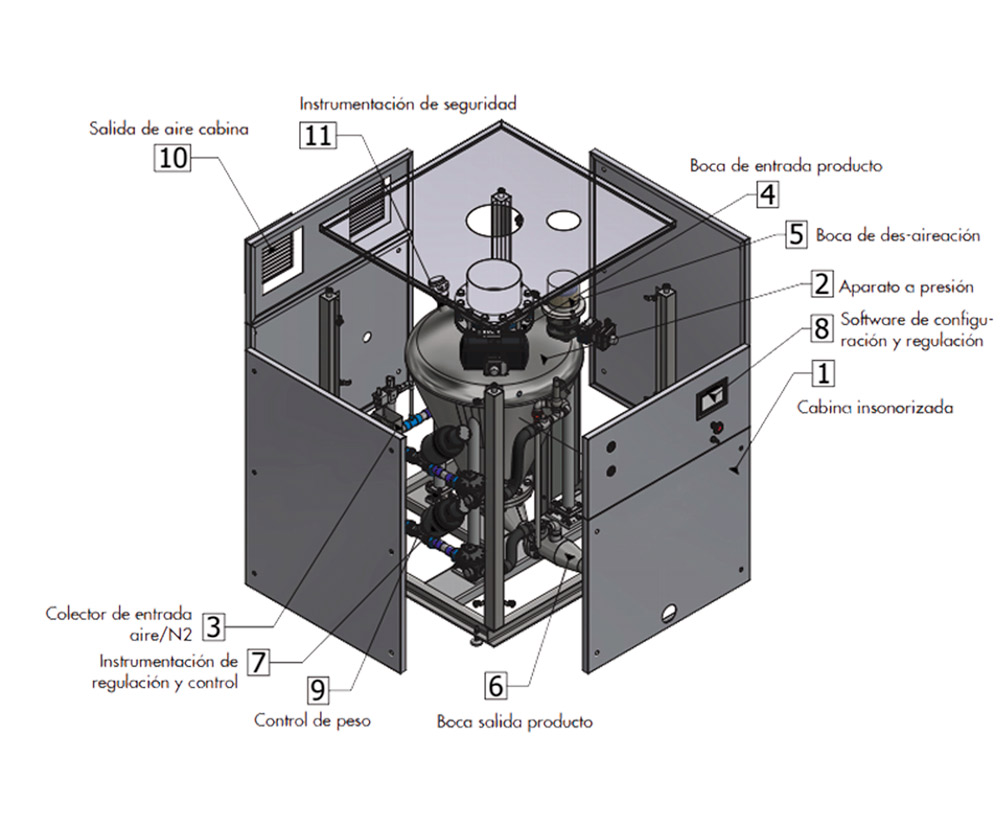

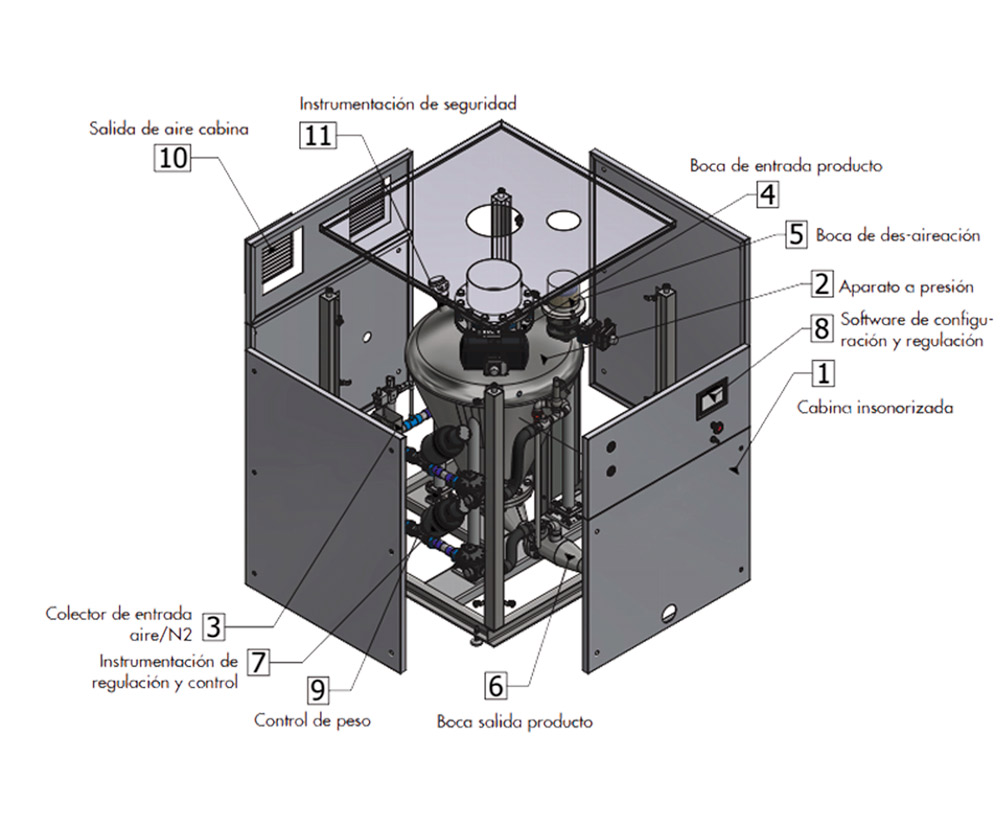

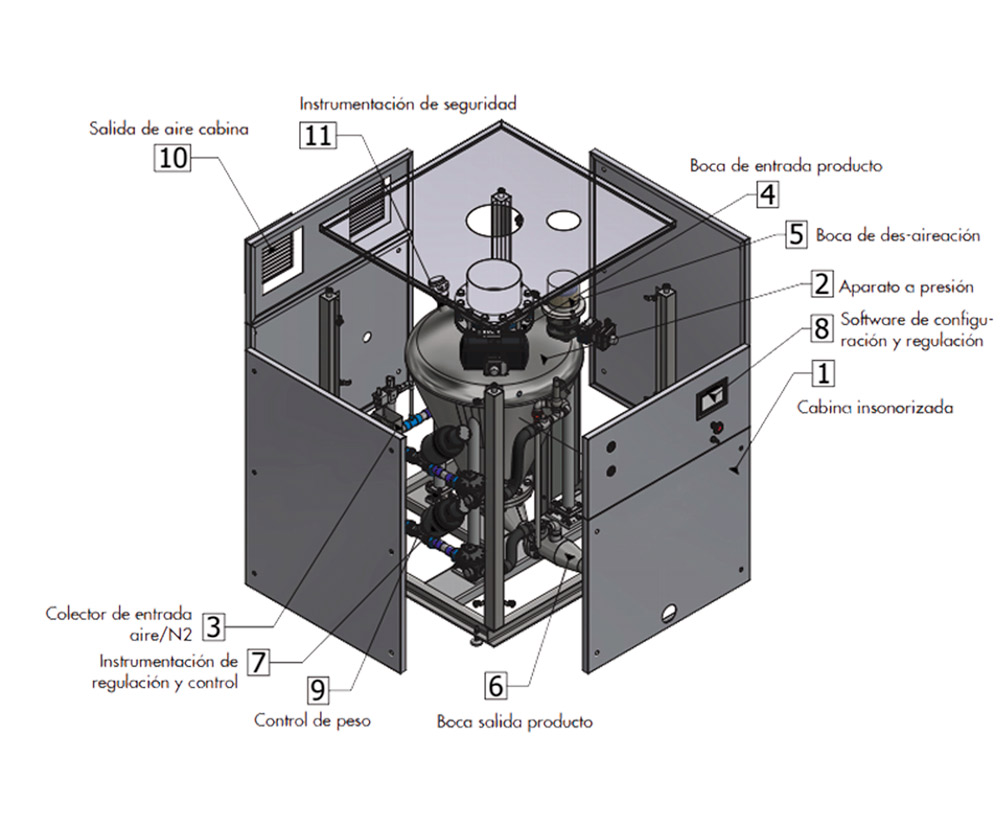

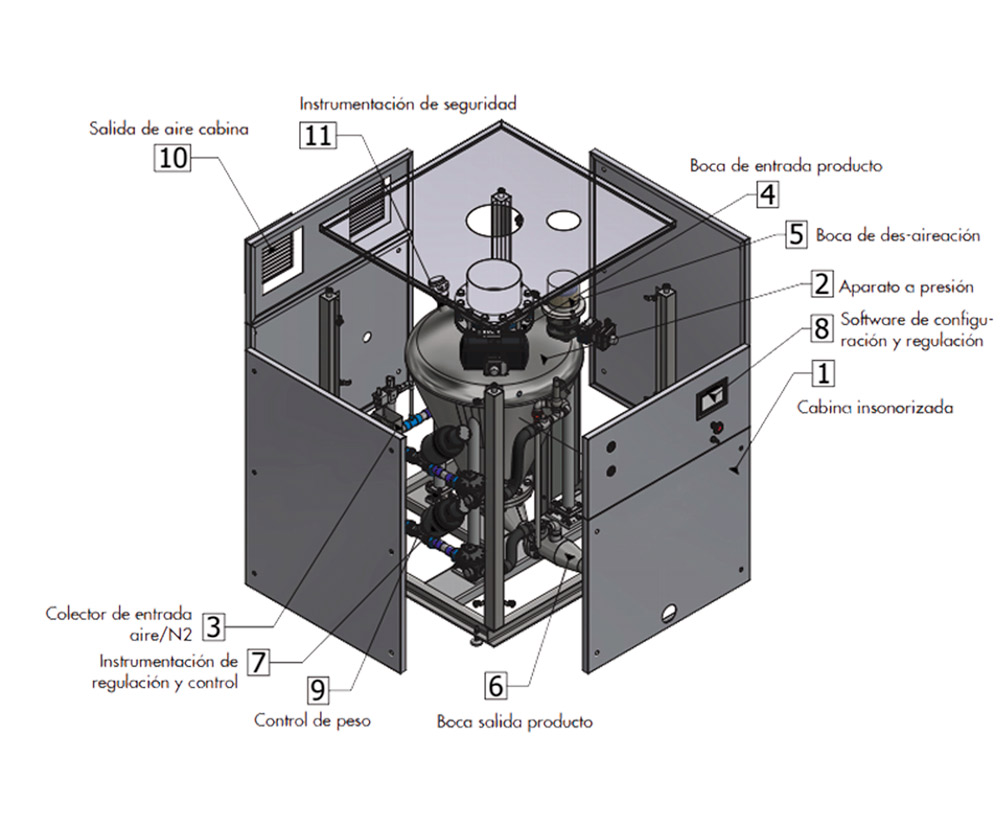

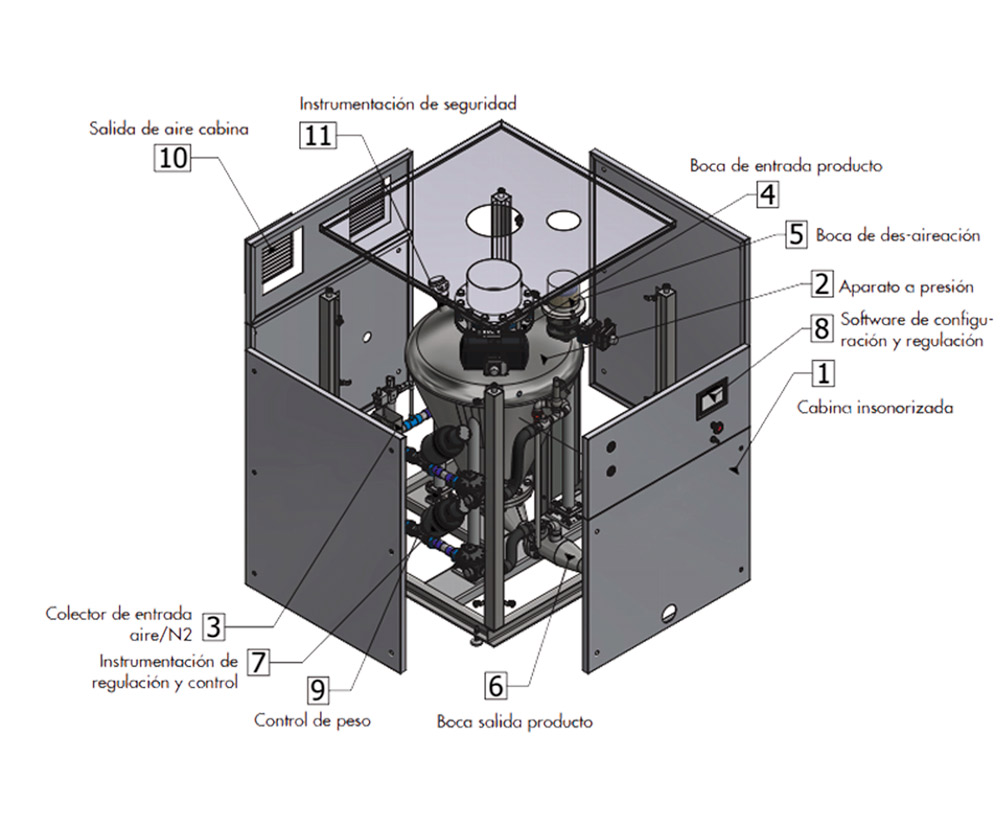

The latest generation evo model Dense Phase Pneumatic Conveying equipment from Equipos y Procesos Levante, mixes optimum design with the latest technology in process control in order to optimise energy consumption, since it automatically adjusts the regulation in both flow and pressure, thus adapting itself to the properties of each raw material.

New Series

Evo-pneumatic

The constant evolution of the industry towards intelligent processes, such as the new manufacturing 4.0 concepts, means that our R&D&i team is constantly evolving, allowing the use of the best available techniques (BAT). As a result, this equipment is unique in the market.

The latest generation evo model Dense Phase Pneumatic Conveying equipment from Equipos y Procesos Levante, mixes optimum design with the latest technology in process control in order to optimise energy consumption, since it automatically adjusts the regulation in both flow and pressure, thus adapting itself to the properties of each raw material.

New Series

Evo-pneumatic

The constant evolution of the industry towards intelligent processes, such as the new manufacturing 4.0 concepts, means that our R&D&i team is constantly evolving, allowing the use of the best available techniques (BAT). As a result, this equipment is unique in the market.

The latest generation evo model Dense Phase Pneumatic Conveying equipment from Equipos y Procesos Levante, mixes optimum design with the latest technology in process control in order to optimise energy consumption, since it automatically adjusts the regulation in both flow and pressure, thus adapting itself to the properties of each raw material.

After years of experience, development and manufacture of pneumatic conveying equipment and installations, one of the learning qualities offered by part of the experience is to define the real needs in each process and its limitations.

These limitations and needs have led to the creation of EVO-PNEUMATIC. Compact, simple and intelligent equipment, which adapts and learns about any raw material to be transferred.

The main advantages over other technologies available on the market are as follows:

Savings

Optimisation of energy consumption

Efficiency

Optimal design and the latest technology

After years of experience, development and manufacture of pneumatic conveying equipment and installations, one of the learning qualities offered by part of the experience is to define the real needs in each process and its limitations.

These limitations and needs have led to the creation of EVO-PNEUMATIC. Compact, simple and intelligent equipment, which adapts and learns about any raw material to be transferred.

The main advantages over other technologies available on the market are as follows:

Savings

Optimisation of energy consumption

Efficiency

Optimal design and the latest technology

After years of experience, development and manufacture of pneumatic conveying equipment and installations, one of the learning qualities offered by part of the experience is to define the real needs in each process and its limitations.

These limitations and needs have led to the creation of EVO-PNEUMATIC. Compact, simple and intelligent equipment, which adapts and learns about any raw material to be transferred.

The main advantages over other technologies available on the market are as follows:

Savings

Optimisation of energy consumption

Efficiency

Optimal design and the latest technology

Discover the main benefits:

Multiproducto

Automatic adjustment for product changeover, as the installations are designed for single products, or with a high regulation for the less favourable product. EVO-PNEUMATIC and its technology automatically allows the change of regulation for each material, adjusted to your process and always offering the highest performance at the lowest consumption, without the need for manual adjustment, either mechanical or via software.

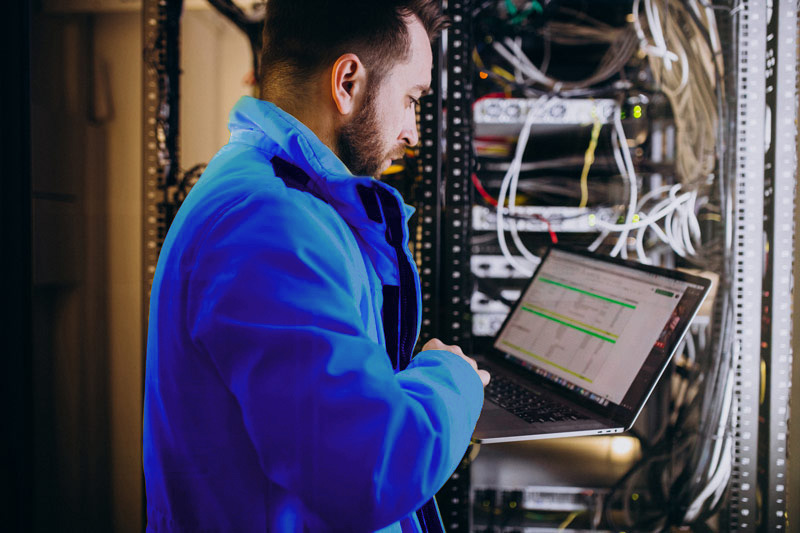

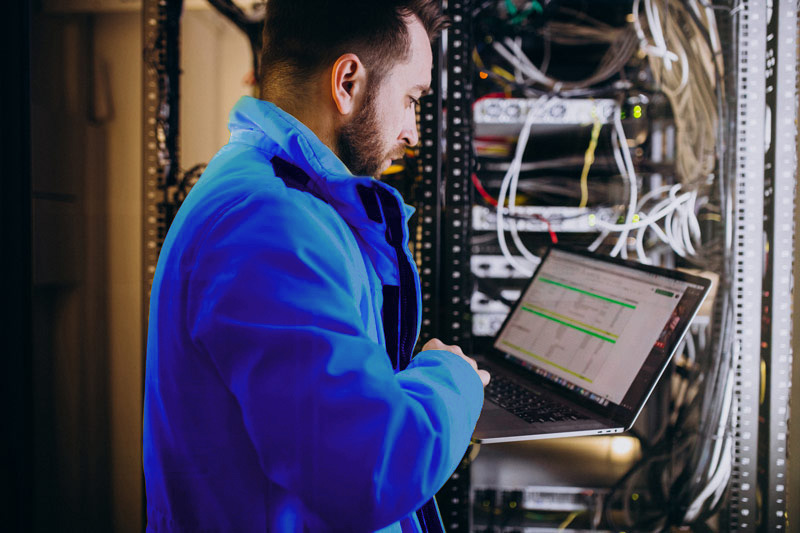

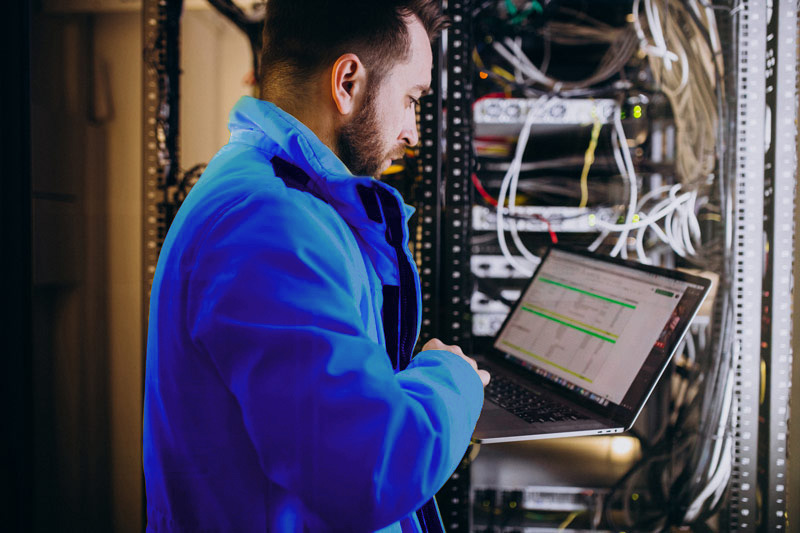

Traceability

The demands of the manufacturing industry are growing and we manufacturers have to adapt to them. EVO-PNEUMATIC sends highly important daily data such as the kg sent per cycle, how many cycles and of which product (if any), air flow used per cycle and, as a result, real consumption per kg transported in kW.

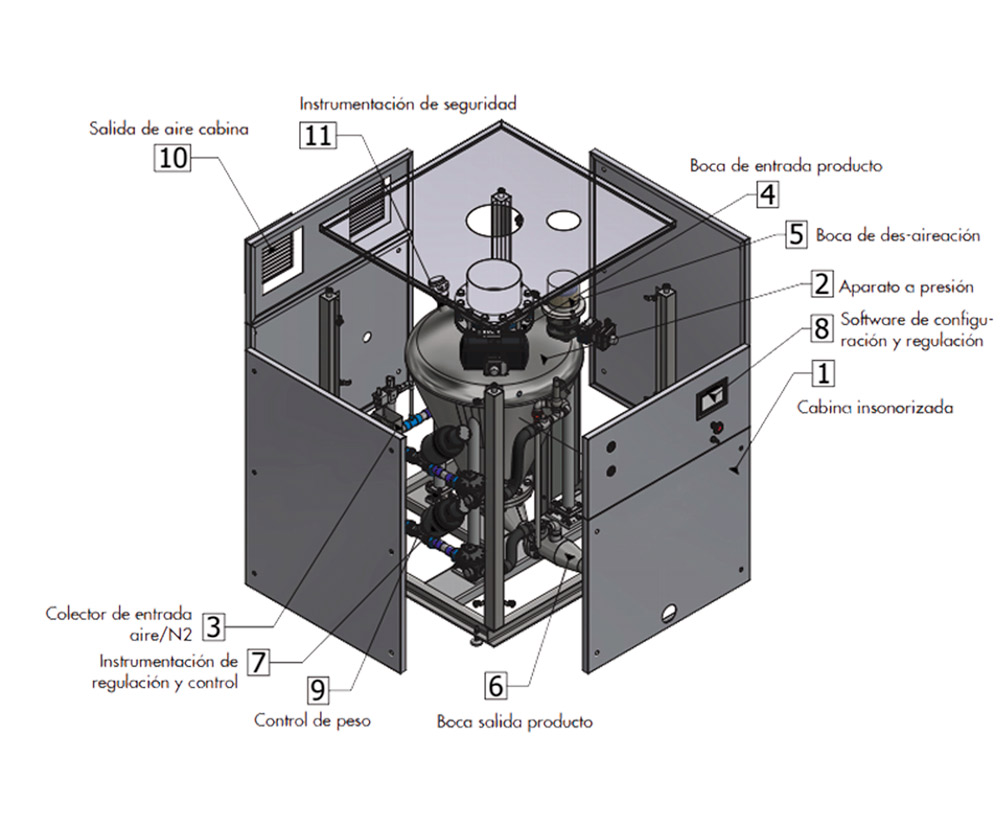

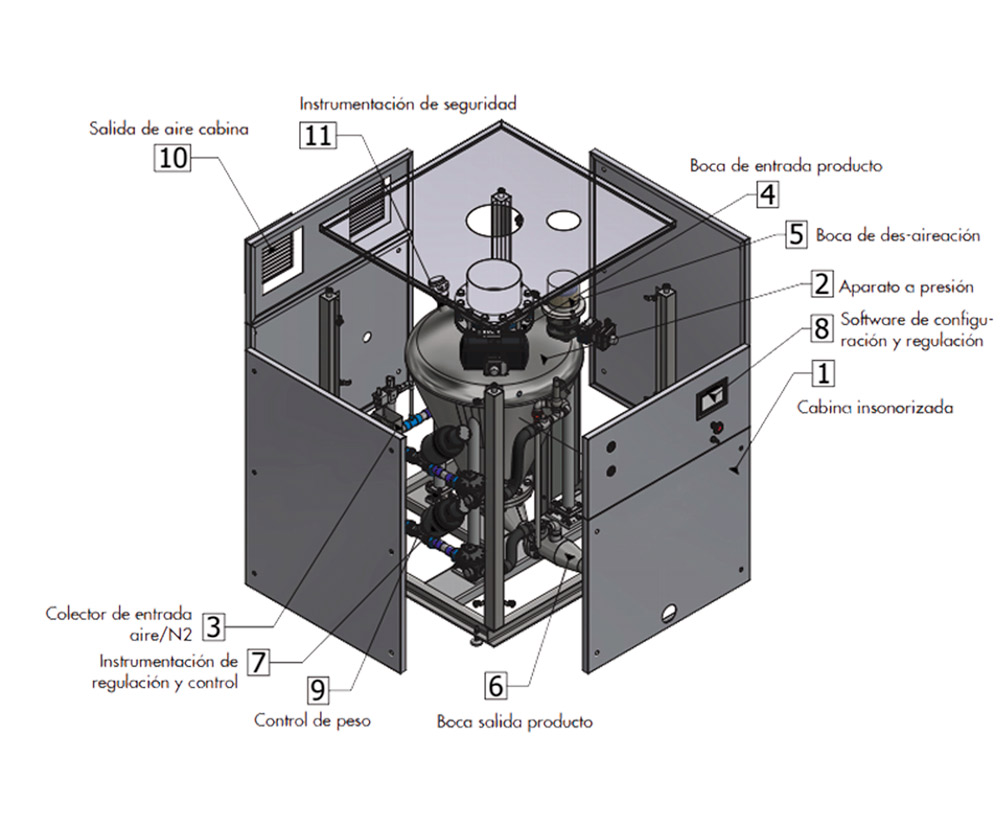

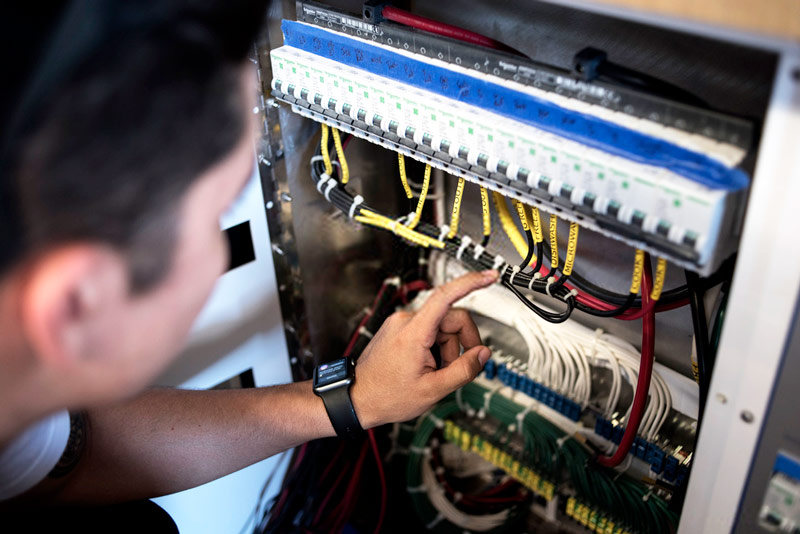

Easy to install

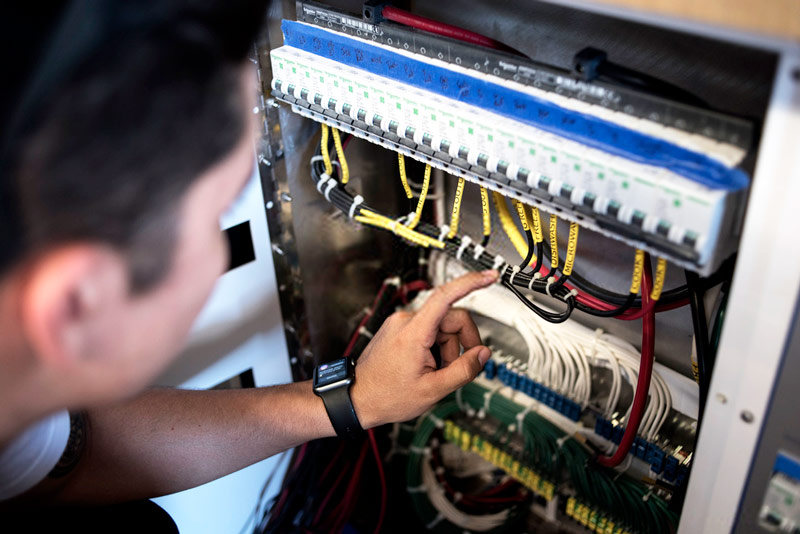

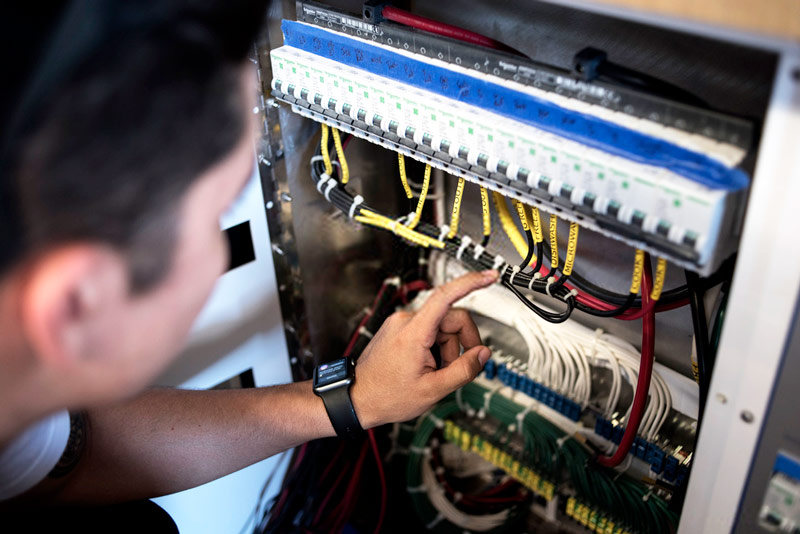

Easy to install and programme, with no need for qualified pneumatic conveying technicians. EVO-PNEUMATIC only requires a 220 V power supply, your compressed air system connection, and the energising/de-energising and de-airing connection. The rest of the characteristics (capacities, distance, etc.) are easily input into our state-of-the-art software, through an HMI screen.

Low consumption

Given the high energy consumption of current pneumatic conveying systems, EVO-PNEUMATIC is automatically regulated cycle by cycle to have the lowest consumption, according to the characteristics of the configured process. Equipped with the latest measuring devices, EVO-PNEUMATIC is capable of giving maximum performance with the lowest consumption.

Discover the main benefits:

Traceability

The demands of the manufacturing industry are growing and we manufacturers have to adapt to them. EVO-PNEUMATIC sends highly important daily data such as the kg sent per cycle, how many cycles and of which product (if any), air flow used per cycle and, as a result, real consumption per kg transported in kW.

Multiproduct

Automatic adjustment for product changeover, as the installations are designed for single products, or with a high regulation for the less favourable product. EVO-PNEUMATIC and its technology automatically allows the change of regulation for each material, adjusted to your process and always offering the highest performance at the lowest consumption, without the need for manual adjustment, either mechanical or via software.

Easy to install

Easy to install and programme, with no need for qualified pneumatic conveying technicians. EVO-PNEUMATIC only requires a 220 V power supply, your compressed air system connection, and the energising/de-energising and de-airing connection. The rest of the characteristics (capacities, distance, etc.) are easily input into our state-of-the-art software, through an HMI screen.

Low consumption

Given the high energy consumption of current pneumatic conveying systems, EVO-PNEUMATIC is automatically regulated cycle by cycle to have the lowest consumption, according to the characteristics of the configured process. Equipped with the latest measuring devices, EVO-PNEUMATIC is capable of giving maximum performance with the lowest consumption.