Knowing and understanding pneumatic conveying systems helps in making decisions when choosing one technology or another. Equipos y Procesos Levante has the experience to design and offer the ideal pneumatic conveying systems for each process.

Our objective is to fully comply with the technical requirements and conditions of each process, with a reasonable and controlled investment taking into account the operating costs and profitability. For this purpose, we have a pilot plant to carry out industrial level tests with your product, checking its behaviour, breakage and disintegration, in order to offer you, with total security, the equipment that best suits your needs.

Depending on the process and product to be conveyed, we use pressure or vacuum pneumatic conveying systems in their different modalities.

Pneumatic conveying systems

Knowing and understanding pneumatic conveying systems helps in making decisions when choosing one technology or another. Equipos y Procesos Levante has the experience to design and offer the ideal pneumatic conveying systems for each process.

Our objective is to fully comply with the technical requirements and conditions of each process, with a reasonable and controlled investment taking into account the operating costs and profitability. For this purpose, we have a pilot plant to carry out industrial level tests with your product, checking its behaviour, breakage and disintegration, in order to offer you, with total security, the equipment that best suits your needs.

Depending on the process and product to be conveyed, we use pressure or vacuum pneumatic conveying systems in their different modalities.

Pneumatic conveying systems

Knowing and understanding pneumatic conveying systems helps in making decisions when choosing one technology or another. Equipos y Procesos Levante has the experience to design and offer the ideal pneumatic conveying systems for each process.

Our objective is to fully comply with the technical requirements and conditions of each process, with a reasonable and controlled investment taking into account the operating costs and profitability. For this purpose, we have a pilot plant to carry out industrial level tests with your product, checking its behaviour, breakage and disintegration, in order to offer you, with total security, the equipment that best suits your needs.

Depending on the process and product to be conveyed, we use pressure or vacuum pneumatic conveying systems in their different modalities.

Conveying in dense phase

Low particle speed (max 5 m/s), minimum flow, high pressure (up to 6 bar). Continuous or discontinuous pneumatic conveying system, by pulse or vacuum, through pressure vessel or rotary valve

Semi-dense phase conveying

Medium particle speed (between 5 and 12m/s) at medium pressure (max 2 bar). Pneumatic conveying system by pulse and/or vacuum, through a pressure vessel.

Diluted phase conveying

High particle speed (up to 30m/s), minimum pressure (up to 1 bar and -500 mbar in negative). Pneumatic conveying system by pulse or vacuum, through rotary piston pumps, high pressure fan, connected to static hoppers or alveolar valves.

Conveying in dense phase

Low particle speed (max 5 m/s), minimum flow, high pressure (up to 6 bar). Continuous or discontinuous pneumatic conveying system, by pulse or vacuum, through pressure vessel or rotary valve

Semi-dense phase conveying

Medium particle speed (between 5 and 12m/s) at medium pressure (max 2 bar). Pneumatic conveying system by pulse and/or vacuum, through a pressure vessel.

Diluted phase conveying

High particle speed (up to 30m/s), minimum pressure (up to 1 bar and -500 mbar in negative). Pneumatic conveying system by pulse or vacuum, through rotary piston pumps, high pressure fan, connected to static hoppers or alveolar valves.

Conveying in dense phase

Low particle speed (max 5 m/s), minimum flow, high pressure (up to 6 bar). Continuous or discontinuous pneumatic conveying system, by pulse or vacuum, through pressure vessel or rotary valve

Semi-dense phase conveying

Medium particle speed (between 5 and 12m/s) at medium pressure (max 2 bar). Pneumatic conveying system by pulse and/or vacuum, through a pressure vessel.

Diluted phase conveying

High particle speed (up to 30m/s), minimum pressure (up to 1 bar and -500 mbar in negative). Pneumatic conveying system by pulse or vacuum, through rotary piston pumps, high pressure fan, connected to static hoppers or alveolar valves.

New developments

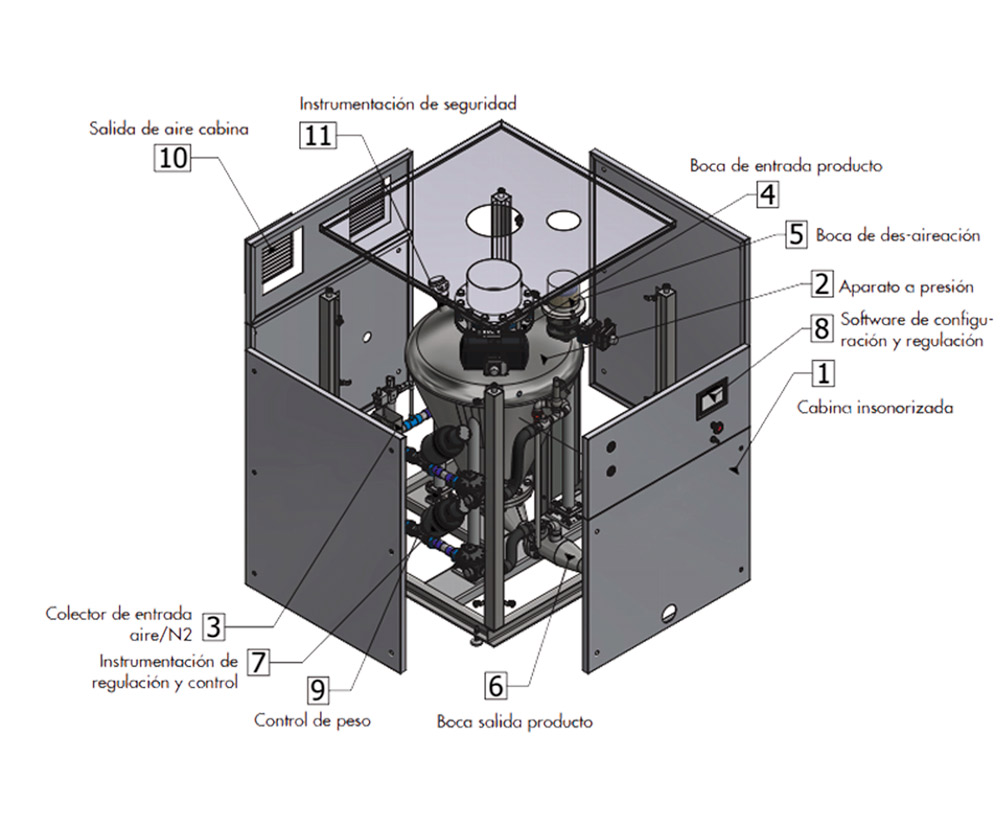

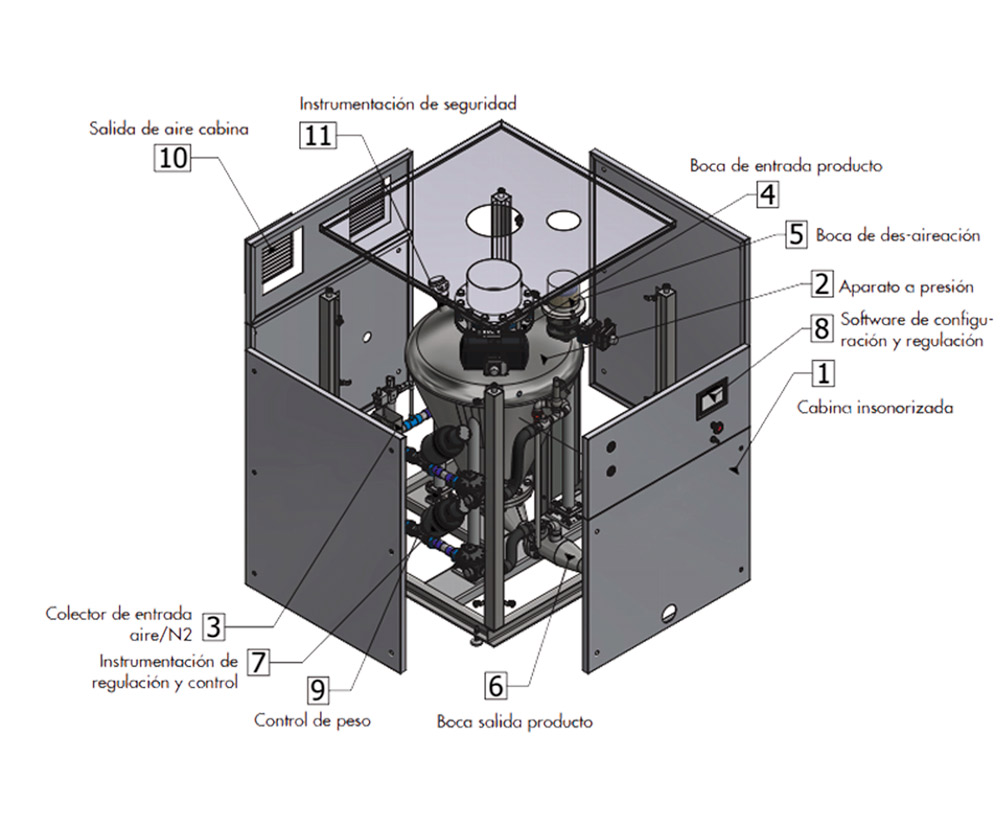

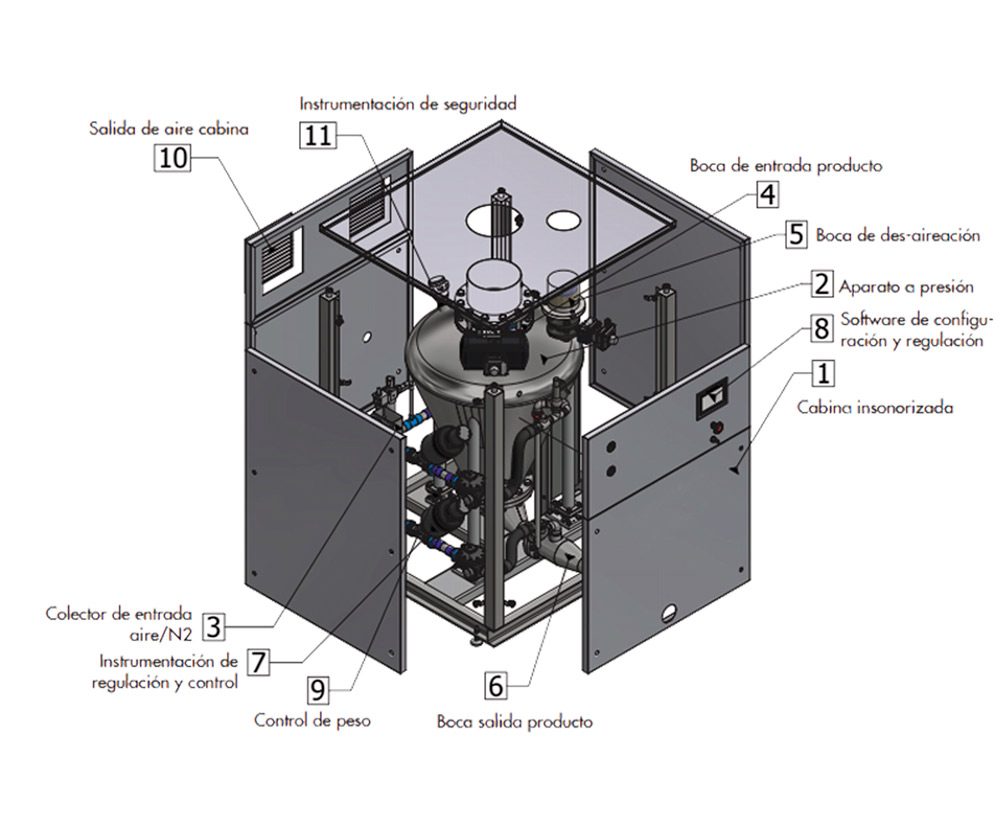

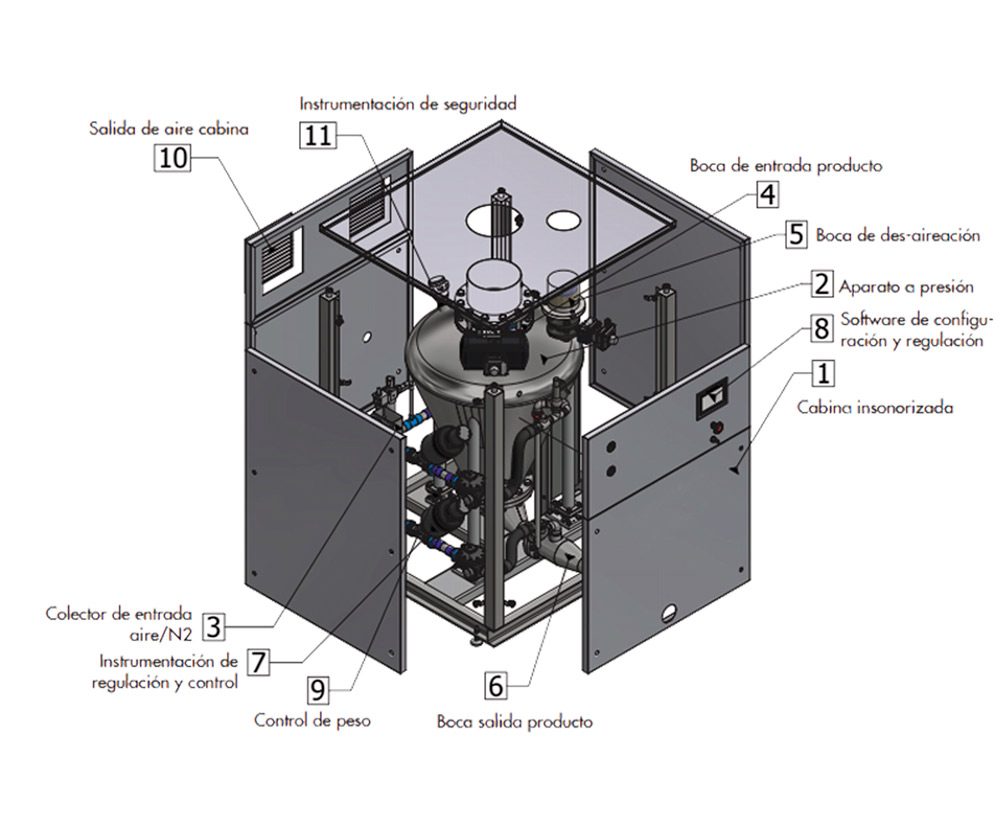

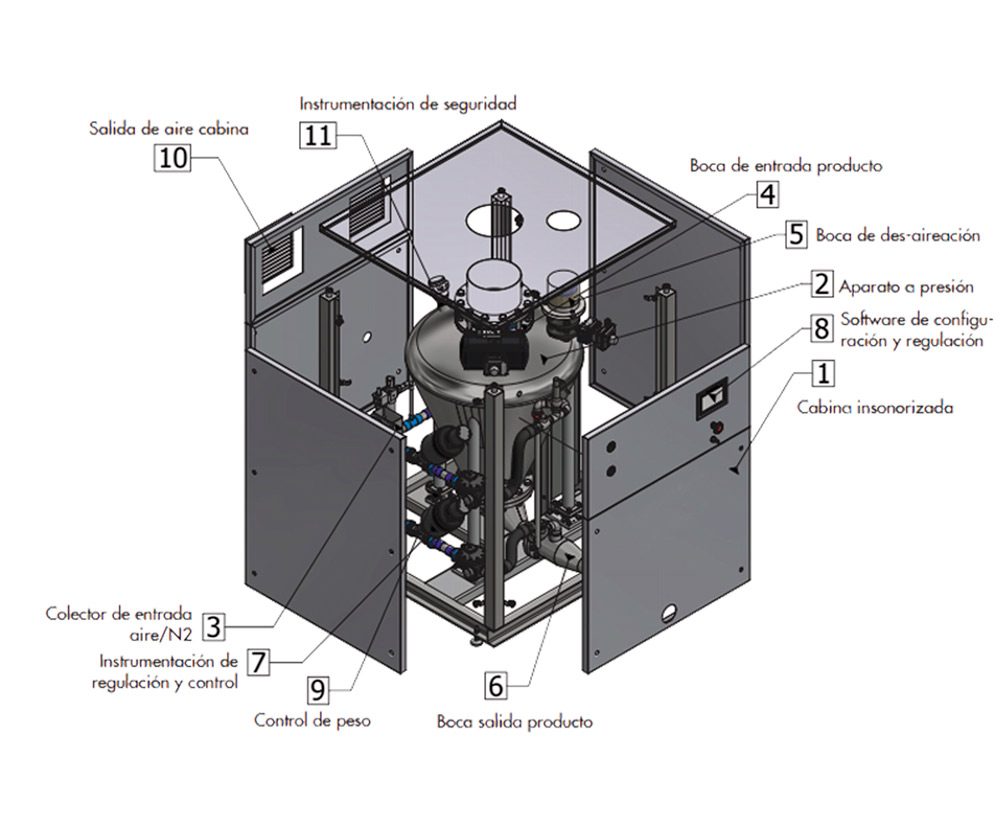

Evo-pneumatic

The constant evolution of the industry towards intelligent processes, such as the new manufacturing 4.0 concepts, means that our R&D&i team is constantly evolving, allowing the use of the best available techniques (BAT). As a result, this equipment is unique in the market.

The latest generation evo model Dense Phase Pneumatic Conveying equipment from Equipos y Procesos Levante, mixes optimum design with the latest technology in process control in order to optimise energy consumption, since it automatically adjusts the regulation in both flow and pressure, thus adapting itself to the properties of each raw material.

Evo-pneumatic

The constant evolution of the industry towards intelligent processes, such as the new manufacturing 4.0 concepts, means that our R&D&i team is constantly evolving, allowing the use of the best available techniques (BAT). As a result, this equipment is unique in the market.

The latest generation evo model Dense Phase Pneumatic Conveying equipment from Equipos y Procesos Levante, mixes optimum design with the latest technology in process control in order to optimise energy consumption, since it automatically adjusts the regulation in both flow and pressure, thus adapting itself to the properties of each raw material.

Evo-pneumatic

The constant evolution of the industry towards intelligent processes, such as the new manufacturing 4.0 concepts, means that our R&D&i team is constantly evolving, allowing the use of the best available techniques (BAT). As a result, this equipment is unique in the market.

The latest generation evo model Dense Phase Pneumatic Conveying equipment from Equipos y Procesos Levante, mixes optimum design with the latest technology in process control in order to optimise energy consumption, since it automatically adjusts the regulation in both flow and pressure, thus adapting itself to the properties of each raw material.

Innovating for the future

After years of experience, development and manufacture of pneumatic conveying equipment and installations, one of the learning qualities offered by part of the experience is to define the real needs in each process and its limitations.

These limitations and needs have led to the creation of EVO-PNEUMATIC. Compact, simple and intelligent equipment, which adapts and learns about any raw material to be transferred.

The main advantages over other technologies available on the market are as follows:

Innovating for the future

After years of experience, development and manufacture of pneumatic conveying equipment and installations, one of the learning qualities offered by part of the experience is to define the real needs in each process and its limitations.

These limitations and needs have led to the creation of EVO-PNEUMATIC. Compact, simple and intelligent equipment, which adapts and learns about any raw material to be transferred.

The main advantages over other technologies available on the market are as follows:

Innovating for the future

After years of experience, development and manufacture of pneumatic conveying equipment and installations, one of the learning qualities offered by part of the experience is to define the real needs in each process and its limitations.

These limitations and needs have led to the creation of EVO-PNEUMATIC. Compact, simple and intelligent equipment, which adapts and learns about any raw material to be transferred.

The main advantages over other technologies available on the market are as follows: