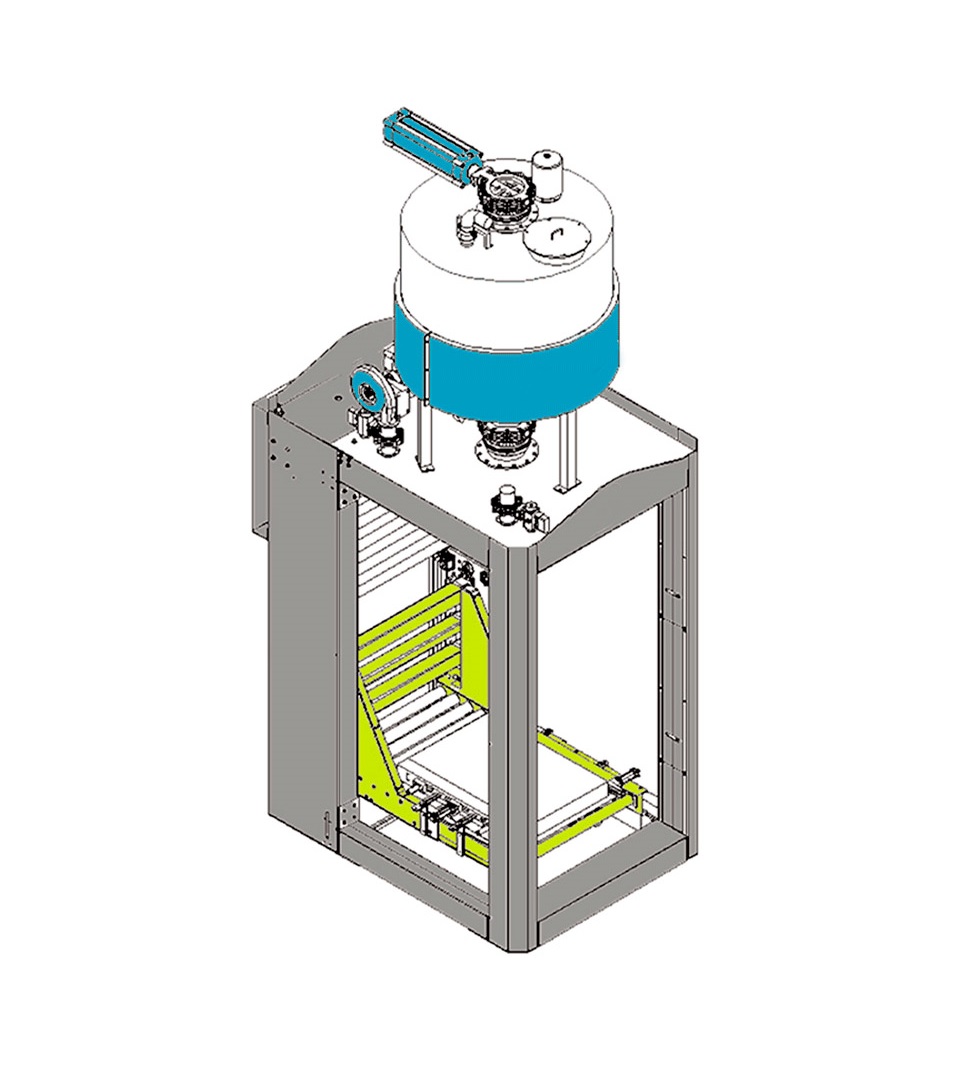

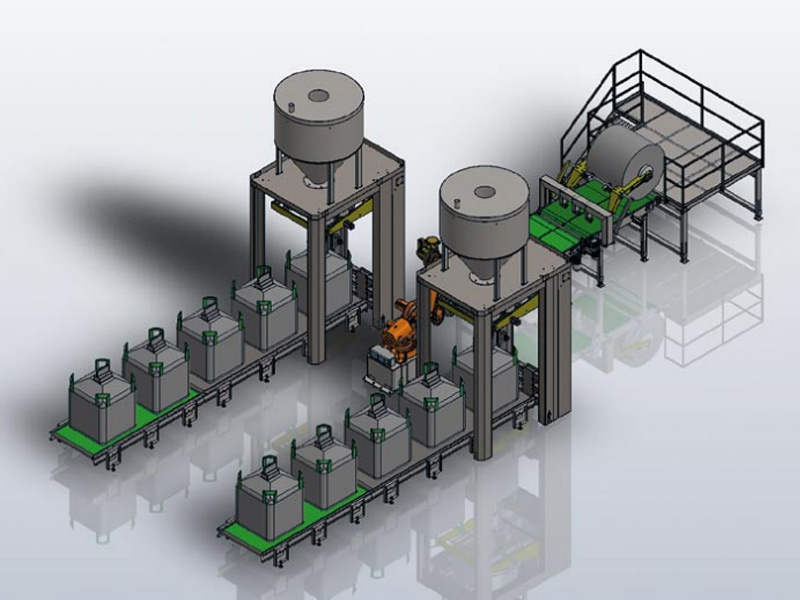

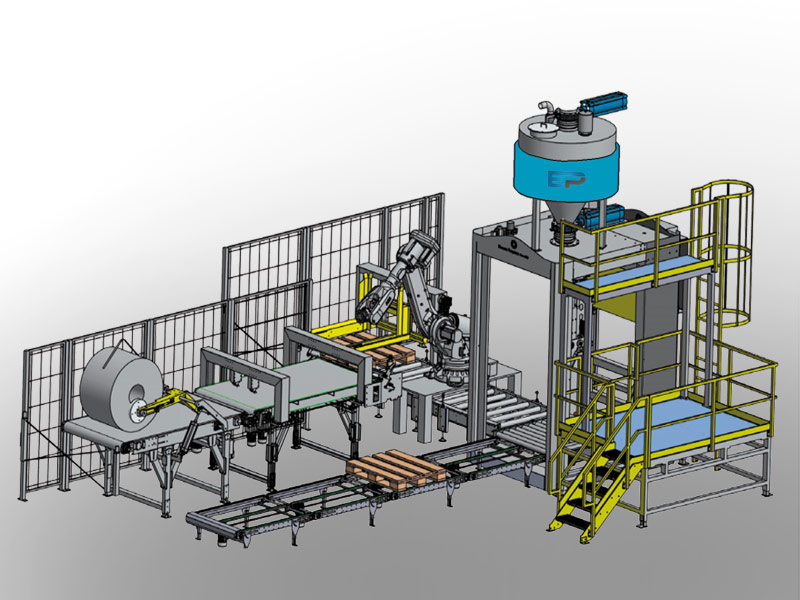

At Equipos y Procesos we design and manufacture complete customised installations for the filling and handling of Big Bags. Introducing the BBA series Big Bag filling station, exclusive on the market.

Throughputs:

1 filling station, semi-automatic: from 60 to 100 BB/hr

The throughput will vary depending on the model of the equipment, the degree of automation of the installation and the type of product to be packed. Once the tests with your product have been carried out in our laboratory, we will indicate the maximum throughput from the equipment.

Semi-automatic filling machines

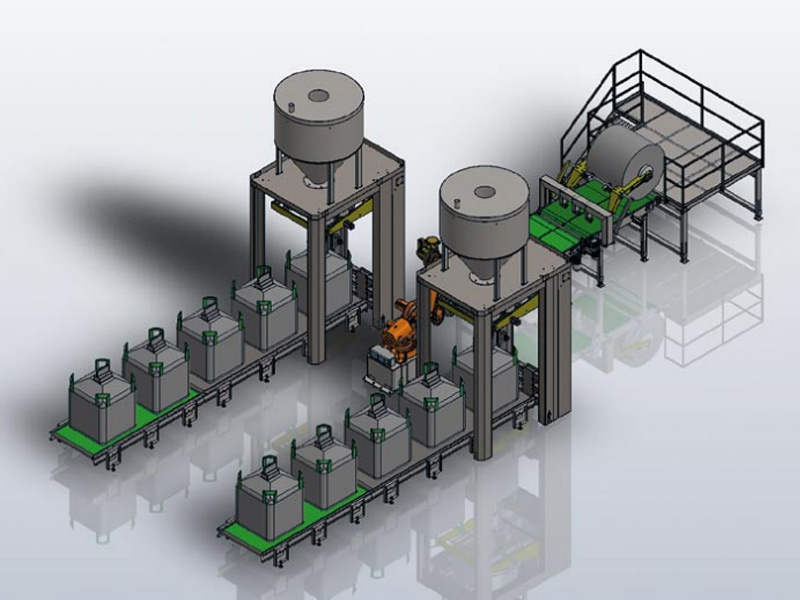

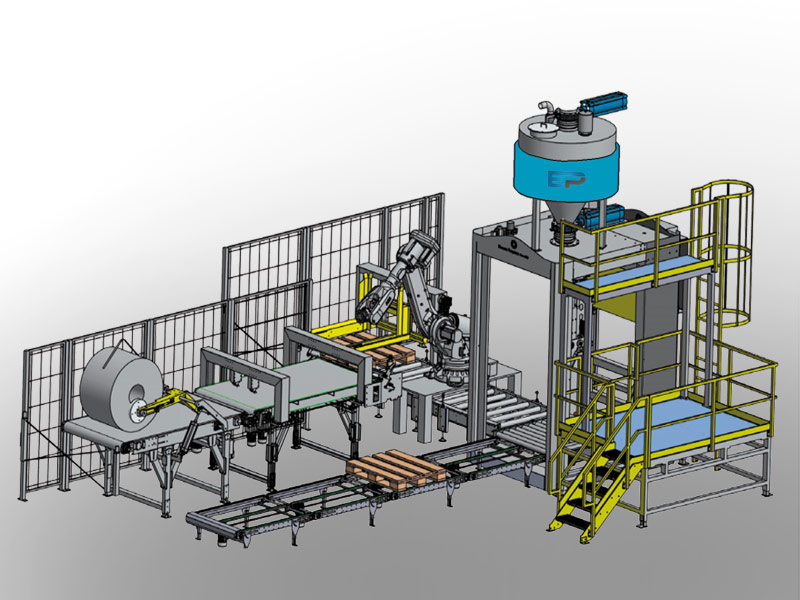

At Equipos y Procesos we design and manufacture complete customised installations for the filling and handling of Big Bags. Introducing the BBA series Big Bag filling station, exclusive on the market.

Throughputs:

1 filling station, semi-automatic: from 60 to 100 BB/hr

The throughput will vary depending on the model of the equipment, the degree of automation of the installation and the type of product to be packed. Once the tests with your product have been carried out in our laboratory, we will indicate the maximum throughput from the equipment.

Semi-automatic filling machines

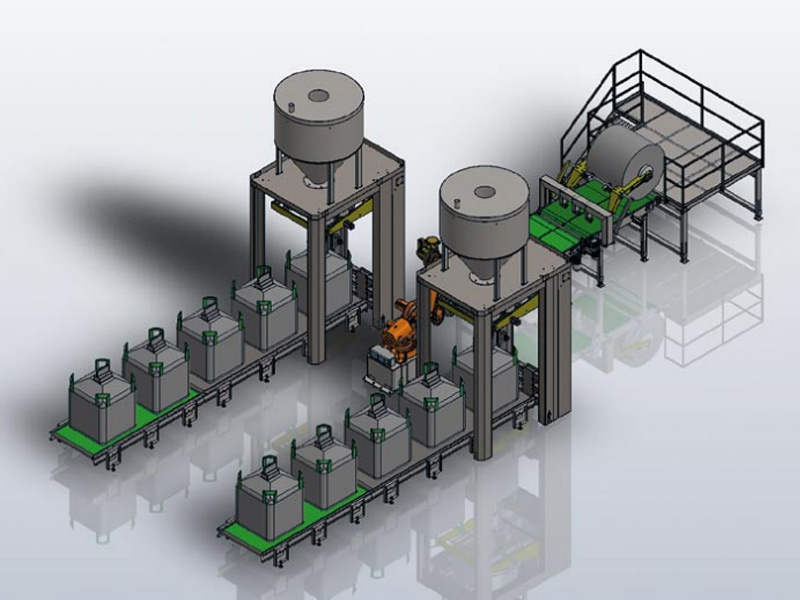

At Equipos y Procesos we design and manufacture complete customised installations for the filling and handling of Big Bags. Introducing the BBA series Big Bag filling station, exclusive on the market.

Throughputs:

1 filling station, semi-automatic: from 60 to 100 BB/hr

The throughput will vary depending on the model of the equipment, the degree of automation of the installation and the type of product to be packed. Once the tests with your product have been carried out in our laboratory, we will indicate the maximum throughput from the equipment.

The basic functions of the Big Bag filling station, automatic BBA series are as follows:

- Weighing hopper.

- Weighing on roller conveyors

- Belt, chain or roller conveyors

- Pallet dispenser

- Placing of cardboard on pallets

- Placing of film on pallets

- Airtight system in filling head

- Suction system inside the bag

- Bag inflation with air or nitrogen

- Sample collection

- Product compacting on roller conveyor

- Heat sealing or ultrasonic bag closing

- Barcode attachment

- Reweighing and checking of full Big Bags

The basic functions of the Big Bag filling station, automatic BBA series are as follows:

Weighing hopper.

Weighing on roller conveyors

Belt, chain or roller conveyors

Pallet dispenser

Placing of cardboard on pallets

Placing of film on pallets

Airtight system in filling head

Suction system inside the bag

Bag inflation with air or nitrogen

Sample collection

Product compacting on roller conveyor

Heat sealing or ultrasonic bag closing

Barcode attachment

Reweighing and checking of full Big Bags

The basic functions of the Big Bag filling station, automatic BBA series are as follows:

Descúbrelas

- Weighing hopper.

- Weighing on roller conveyors

- Belt, chain or roller conveyors

- Pallet dispenser

- Placing of cardboard on pallets

- Placing of film on pallets

- Airtight system in filling head

- Suction system inside the bag

- Bag inflation with air or nitrogen

- Sample collection

- Product compacting on roller conveyor

- Heat sealing or ultrasonic bag closing

- Barcode attachment

- Reweighing and checking of full Big Bags

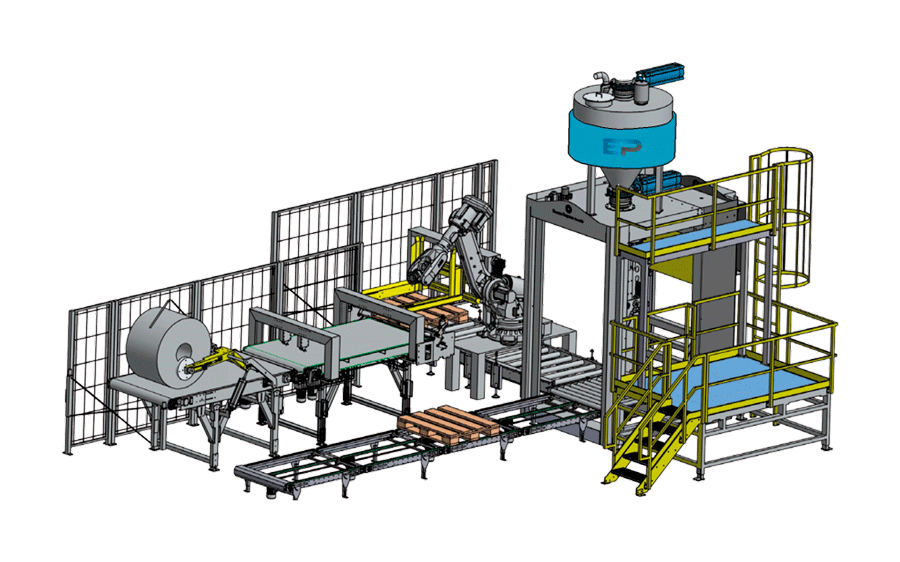

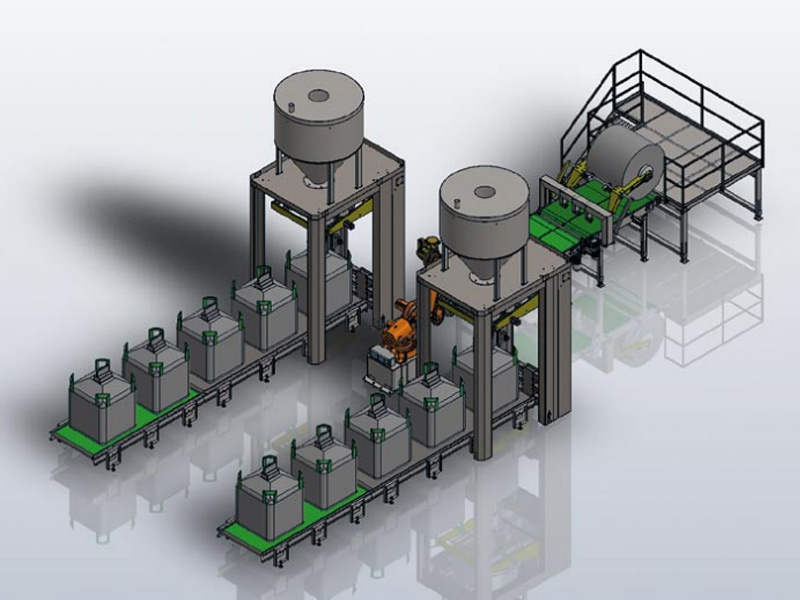

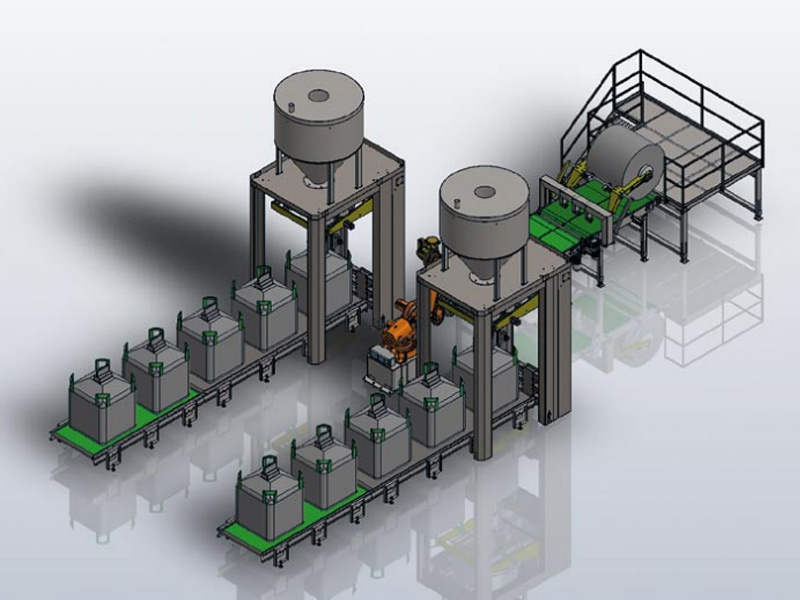

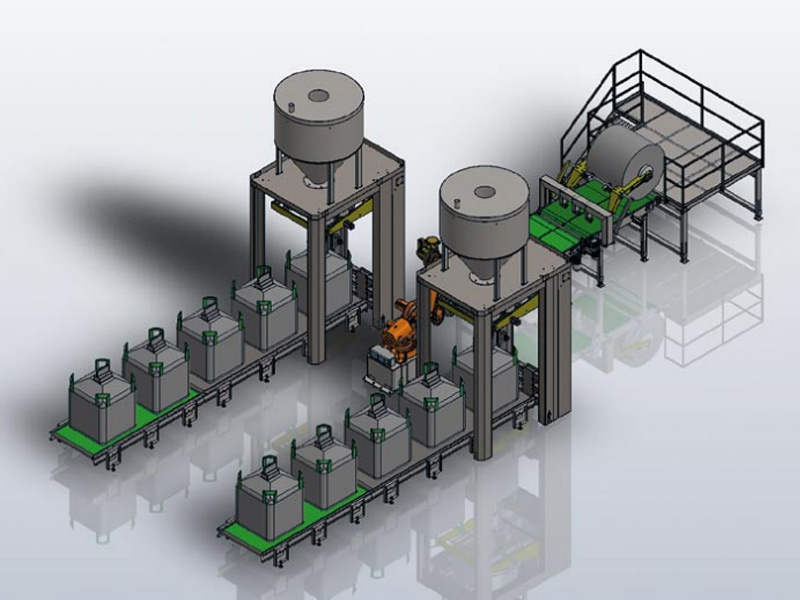

Automatic filling machines

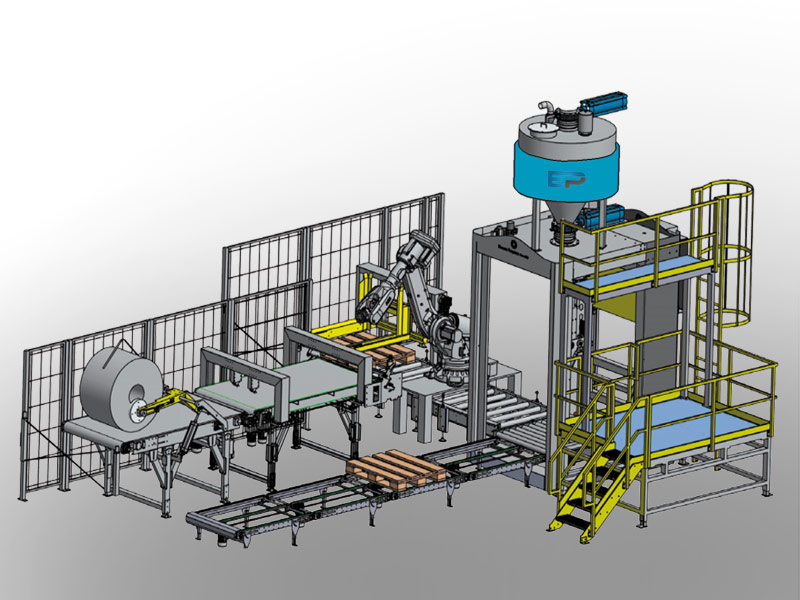

At Equipos y Procesos Levante we design and manufacture complete customised installations for the filling and handling of Big Bags. We have standard equipment to provide a quick and economical response, but we also adapt to the needs of each process, designing and adapting our equipment for its optimal application.

The throughput of our equipment varies mainly depending on the product to be packaged, the type of filling station chosen and its degree of automation. Once the tests with your product have been carried out in our laboratory, we will indicate the maximum throughput of the equipment.

Our equipment units are mainly grouped into 3 families:

Big Bag filling stations by net weight

Big Bag filling stations by gross weight.

Station for fully automatic Big Bag filling. NEW

Automatic filling machines

At Equipos y Procesos Levante we design and manufacture complete customised installations for the filling and handling of Big Bags. We have standard equipment to provide a quick and economical response, but we also adapt to the needs of each process, designing and adapting our equipment for its optimal application.

The throughput of our equipment varies mainly depending on the product to be packaged, the type of filling station chosen and its degree of automation. Once the tests with your product have been carried out in our laboratory, we will indicate the maximum throughput of the equipment.

Our equipment units are mainly grouped into 3 families:

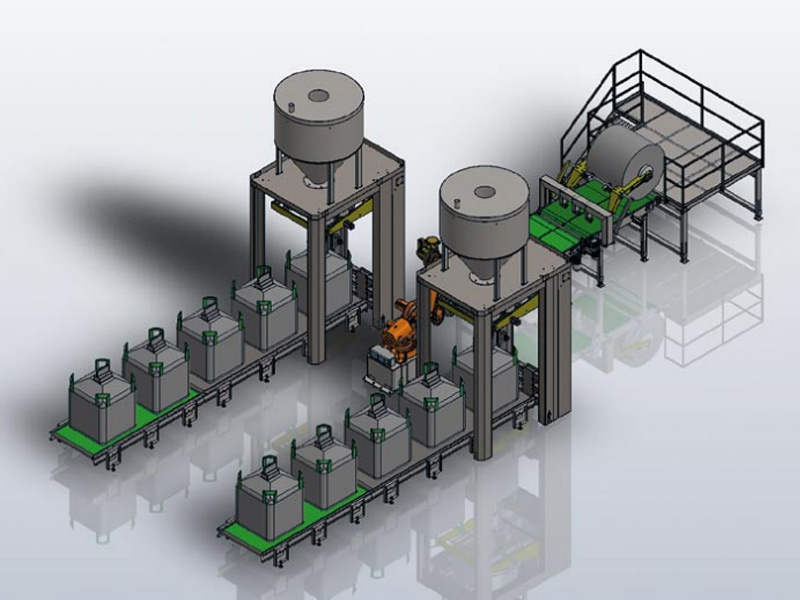

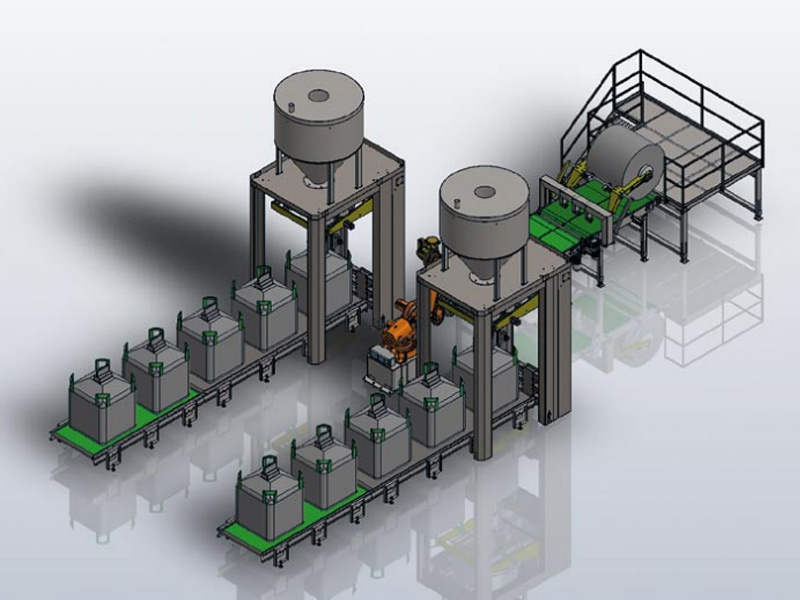

Automatic filling machines

At Equipos y Procesos Levante we design and manufacture complete customised installations for the filling and handling of Big Bags. We have standard equipment to provide a quick and economical response, but we also adapt to the needs of each process, designing and adapting our equipment for its optimal application.

The throughput of our equipment varies mainly depending on the product to be packaged, the type of filling station chosen and its degree of automation. Once the tests with your product have been carried out in our laboratory, we will indicate the maximum throughput of the equipment.

Our equipment units are mainly grouped into 3 families:

Big Bag filling stations by net weight

Big Bag filling stations by gross weight.

Station for fully automatic Big Bag filling.

-NEW-

All our equipment is modular, this allows it to be configured with different accessories:

- Pallet dispenser

- Placing of cardboard on the pallet

- Heat sealing or ultrasonic bag closing

- Bag inflation with air or inert gas

- Airtight system in filling head

- Suction system inside the bag

- Sample collection

- Barcode attachment

- Weighing on roller conveyors

- Belt, chain or roller conveyors

- Product compacting on roller conveyor

- Heat sealing or ultrasonic bag closing

All our equipment is modular, this allows it to be configured with different accessories:

Pallet dispenser

Placing of cardboard on the pallet

Heat sealing or ultrasonic bag closing

Bag inflation with air or inert gas

Airtight system in filling head

Suction system inside the bag

Sample collection

Barcode attachment

Weighing on roller conveyors

Belt, chain or roller conveyors

Product compacting on roller conveyor

Heat sealing or ultrasonic bag closing

All our equipment is modular, this allows it to be configured with different accessories:

Accesorios

- Pallet dispenser

- Placing of cardboard on the pallet

- Heat sealing or ultrasonic bag closing

- Bag inflation with air or inert gas

- Airtight system in filling head

- Suction system inside the bag

- Sample collection

- Barcode attachment

- Weighing on roller conveyors

- Belt, chain or roller conveyors

- Product compacting on roller conveyor

- Heat sealing or ultrasonic bag closing

We design and manufacture machines for weighing and packing bags of solid bulk materials, both for powder and granular products.

LEARN MORE

Equipos y Procesos Levante has the experience to design and offer the ideal pneumatic conveying systems for each process.